Vacuum Pressing Rotary Vane Vacuum Pumps & Compressors

Many building materials are adhered together to increase thickness and structural integrity, as well as to imbue various other physical properties. It is still argued which method is best for ensuring an even and secure press, with each method exhibiting specialization or drawbacks. Out of these, the most versatile and secure method is vacuum pressing.

Vacuum pressing at its simplest entails loading a thin plastic or rubber bag with the building materials and adhesive in the order and shape it is to take in its final form. This is particularly beneficial when constructing anything with wood, such as with veneering, tabletops, and walls. To make sure that the materials are adhered evenly and tightly, the materials are often pressed together. The bag is sealed and evacuated using a vacuum pump to a very high magnitude of negative pressure.

The pressure inside of the bag is so low that the atmospheric pressure rushes around the bag, pushing the material within the bag tightly together. As the adhesive cures or dries in between the layers of building material, it is pressed and distributed evenly across the surface area of the construction material due to the strong positive pressure of the atmosphere in comparison to the extreme vacuum conditions within the bag due to the suction of the vacuum pump.

There are various ways to develop a setup for vacuum pressing, but the working principle is generally the same across bags, tables, and everything in between. Strong negative pressure within a film or container causes the atmospheric pressure to move “down the pressure gradient” and press on the material on all sides. Larger pressure will always tend towards lower values of pressure in order to reach a state of pressure equilibrium according to Boyle’s law, as is similarly the case with hot temperature mediums tending to distribute the heat energy towards cold temperature mediums towards a state of thermal equilibrium as states the second law of thermodynamics.

The end result is an evenly pressed piece of laminate material. Vacuum pressing is used for wooden veneering to bend the wood in a specific manner for use in flooring, furniture, or architecture. Various resins and adhesives can be added for extra strength, ductility, and color. This technique is applied to the manufacture of helicopter blades to firmly secure its layers together while keeping it elastic so that it can absorb external vibrations, forces, and moments while in the air.

View our Products

-

-

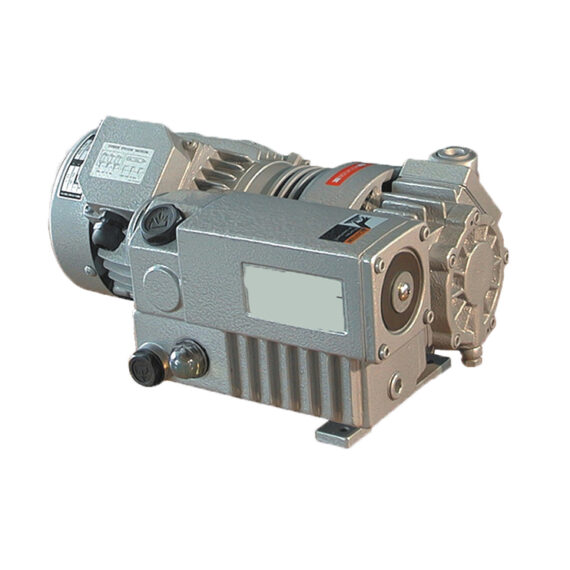

NDRV Series – Dry Running Rotary Vane Vacuum Pumps – Small Capacity

$1,114.67 – $2,327.11 Select optionsAdded

Applications of NES Vacuum Pumps

The strongest of the widely used vacuum generators is the oil-circulated rotary vane vacuum pump. It has the highest cost among the venturi and dry-running rotary vane vacuum pump, but also achieves the highest level of vacuum pressure. For non-commercial application, the oil-circulated rotary vane vacuum pump is not practical, but for all commercial uses, this pump has the capabilities to perform beyond sufficient levels, even capable of providing multiple vacuum tables with the required level of vacuum pressure simultaneously.

The oil-sealed rotary vacuum pump is commonly used for applications where laminate materials need to be pressed to an elevated amount due to the physical properties of the material hindering the spreading effect that the pressing ahs on the adhesive, or for applications where a singular pump is required to provide multiple presses with enough vacuum to press the material to a sufficient extent that is lesser than in the first case.

The rotary vane vacuum pump is connected through multiple plastic tubes to the inside of the bag and pulls the bag tight. The tubes must not be on top of or near the material, or the pressure distribution will vary across it. Thus, the bag is made to be larger than the material to be pressed.

Advantages of NES Vacuum Pumps

For applications that require a higher level of vacuum or sustained vacuum for multiple presses, NES Company Inc. offers the NRV Series oil-circulated rotary vane vacuum pump as a cut above the rest. The NRV Series model rotary vane pumps are constructed to be robust and simple, perfect for a long lasting service life and simple DIY maintenance and repair.

NES Company Inc. offers competitive prices for the already competitively inexpensive rotary vane vacuum pumps, complete with our offer of spare parts kits and optional accessories that can make your NRV Series rotary vane vacuum pump perform better for longer, tailor-made for your industry.