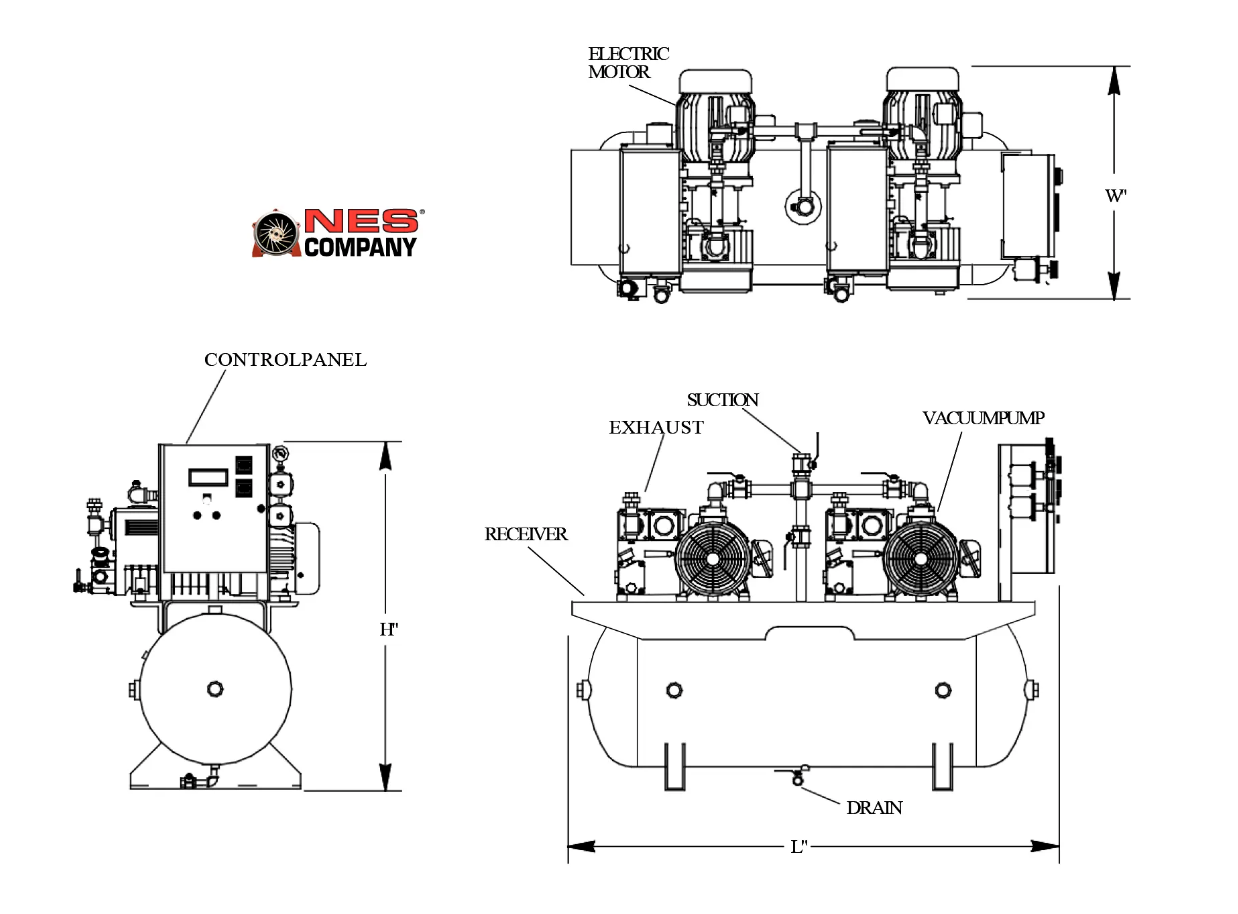

Rotary Vane Duplex Medical Vacuum System

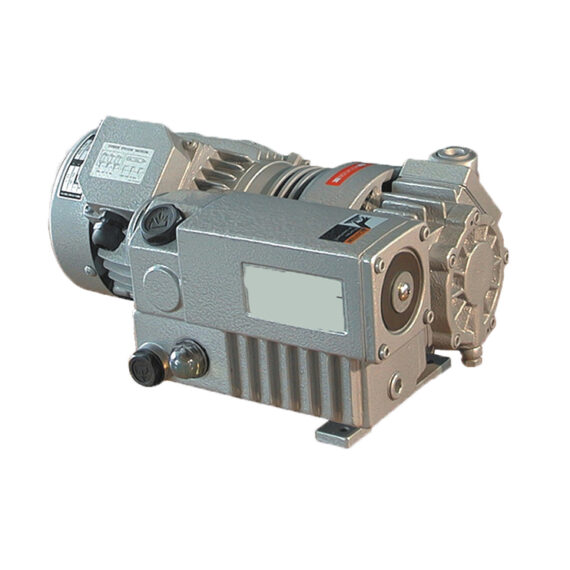

1-10 HP Rotary Vane Vacuum Pump Systems

NOTICE

1. To convert free air capacity (SCFM) to expanded air capacity (ACFM), multiply SCFM by 2.74

2. Maximum ambient temperature: 100ºF for standard systems

3. Clearance: allow 36 in front of control panel and 24 inches around all other sides

4. Dimensions are subject to change

Control Panel Options

LEVEL 1 TOUCH SCREEN HMI:

A 3.5” touch screen with screen displays with:

• Vacuum transducer with back-up vacuum switch

• Service alerts, runtime hour meters, system status, system vacuum level

• Visual/audible alarm indications with isolated contacts for all standard remote alarms

• Event log recording alarms and system activity

• BacNet Gateway: Optional

LEVEL 2 TOUCH SCREEN HMI

A 5” touch screen with screen displays with:

• Vacuum transducer with back-up vacuum switch

• Service alerts, runtime hour meters, system status, system vacuum level

• Visual/audible alarm indications with isolated contacts for all standard remote alarms

• Event log recording alarms and system activity

Options:

• Ethernet connectivity and embedded web page for remote monitoring of alarms and system status, Electronic notifications of alarms and warnings

• BacNet Gateway

Warranty

The Medical Vacuum system is guaranteed by the manufacturer for a period of 12 months from the date of start-up or 18 months from the date of shipment (whichever comes first) against defects in design, materials, or construction.

Optional System Accessories

• Level 1 touch screen HMI

• Level 2 touch screen HMI

• BacNet Gateway

• Rust protection receiver lining

• Galvanized receiver

• Bacteria inlet filter with flask

• External intake filters

• Receiver gauge glass

• Exhaust muffler

• Ethernet Connectivity