The NES Perspective: Polycarbonate Board Manufacturing

Polycarbonate board manufacturing is shaped by vacuum and pressure, from raw material handling to final molding. When atmospheric conditions are mastered in this industry, consistency follows – turning complex chemistry into a repeatable, reliable, high performance product.

- Reactions

- Degassing

- Pneumatic Conveying

- Thermoforming

Polycarbonate board manufacturing involved specialized processes requiring precision control over atmospheric conditions to consistently produce high-quality product. Vacuum and pressure technologies are integral to each critical production stage.

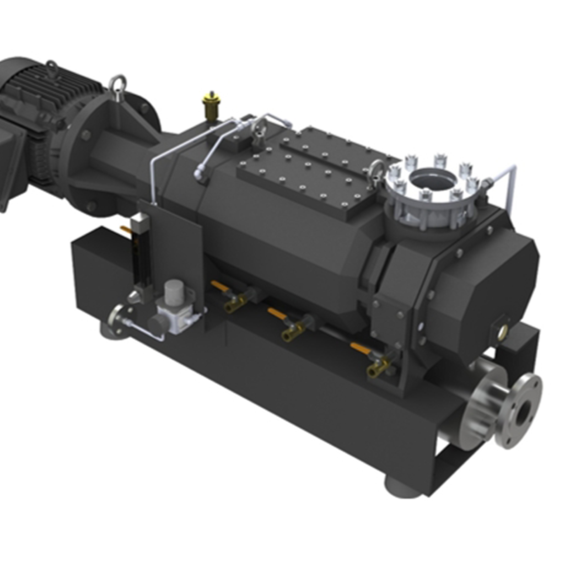

Throughout PC manufacturing facilities, pneumatic conveying systems handle raw materials, additives and resin pellets. Vacuum conveying systems or pressure conveying systems work in tandem with metering airlock valves to transport granular materials and powders quickly and safely, minimizing contamination and environmental exposure. Pneumatic systems ensure consistent raw material flow, precise dosing, and reduced manual handling, significantly enhancing process reliability and cleanliness.

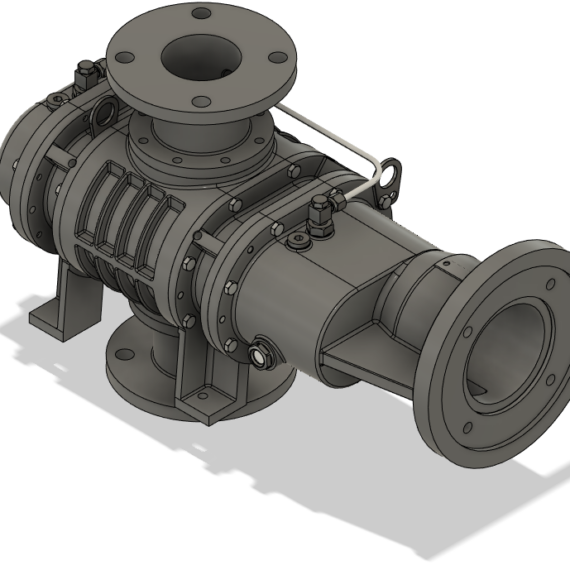

Polycarbonate (PC) synthesis typically involves either a melt transesterification process or the reaction of bisphenol-A (BPA) with phosgene. During this reaction, vacuum systems carefully remove byproducts like hydrochloric acid and phenol, enhancing reaction completion and polymer purity while maintaining a tight grip on harmful gasses. Accurate vacuum control keeps byproducts out to maintain optimal reaction conditions such that the polymer quality is consistent every time.

Degassing processes make use of vacuum to remove entrapped gasses, residual monomers, volatile organic compounds, and moisture from molten PC. These hindrances cause material integrity to decrease drastically, so removing them in this way ensures uniform clarity and structural integrity.

Once the polycarbonate sheet or board has been formed into its basic shape (after degassing), they can be introduced to a further step, being heated and shaped into desired forms via thermoforming. Vacuum technology plays a central role in this process, pulling softened PC sheets firmly against carefully engineered precision molds as the sheet is lowered on. This allows for much more detailed design to come from such a mass-manufacturing setup, ensuring high-quality, dimensionally accurate PC products suitable for diverse applications.

By integrating vacuum and pressure technologies into polycarbonate board manufacturing, manufacturers achieve exceptional product quality, enhanced production efficiency, and consistent, reliable performance of polycarbonate products across multiple industries.