Drying for Dry Screw Vacuum Pumps

Drying is the process of water evaporation from a solid product to increase its quality. This is applicable for leather, pharmaceutical products, chemical industry powders, dyes, certain food products, plastics, and building materials. Using vacuum in the drying process decreases operation time and allows for finer control of moisture content, boosting the efficiency and quality of the procedure.

The concept of vacuum drying stems from the principle that lowering the pressure of a liquid’s surroundings lowers the boiling point of that liquid. The boiling point of a given liquid is dependent on its viscosity, vapor pressure, and the pressure of the air above it. Atmospheric pressure exerts a force down on the liquid molecules as the ambient air molecules are drawn towards the center of the Earth by its gravitational pull. When liquid is heated, the molecules are excited and begin to move, converting the heat energy into kinetic energy. The energy reaches an extent where the intermolecular bonds in the liquid begin to break, causing the phase shift of evaporation. When the pressure that ambient air exerts decreases, the heat energy required to break the intermolecular bonds of the liquid decreases as well.

Applications of Dry Screw Vacuum Pumps

This principle is extremely useful when applied to vacuum drying. Many organic compounds are prone to decay and degradation when heated to an excessive degree; this can be observed in wood, which burns and decays rather than melting in a fire. Thus, evacuating the drying chamber and releasing the liquid of atmospheric pressure decreases the heat energy required for evaporation and proper drying so that organic compounds used in food, chemical, and pharmaceutical products and samples are conserved with the highest possible yield.

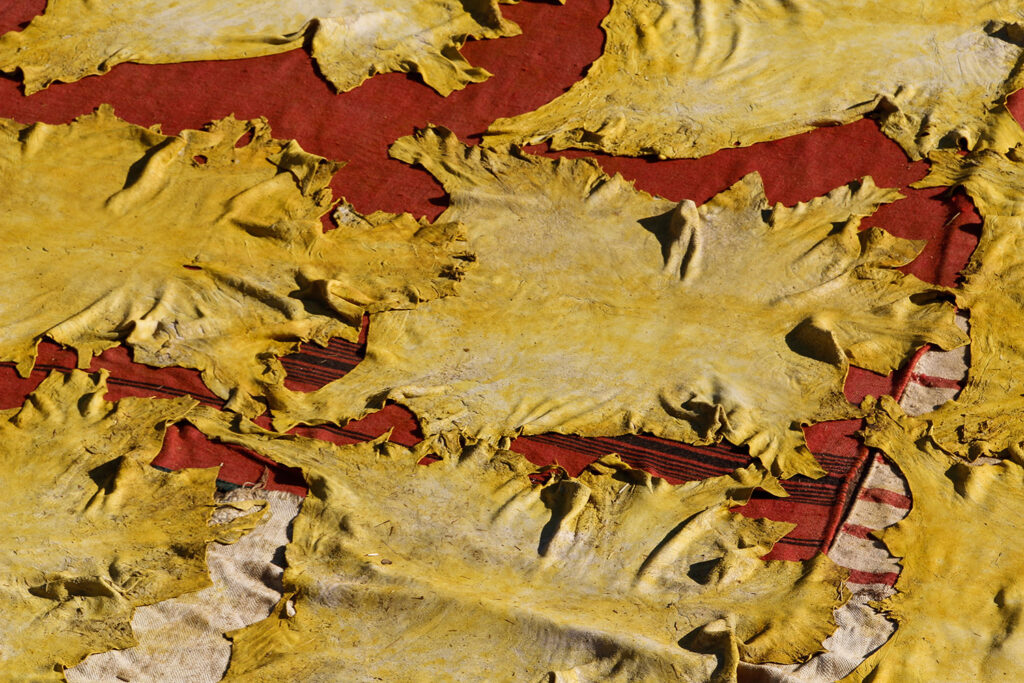

Depending on the product, the apparatus used for vacuum drying differs. Leather is typically dried on vacuum tables. Leather is laid flat on a table and a press is brought down. The press has perforations through which suction is pulled. The moisture within the leather is brought towards the press and drawn out of the grain, drying the leather. For most food and chemical products, a chamber is filled with product and evacuated while slightly heated. The drop in pressure causes the boiling point of the water within the product to be drawn out, with which the heat is used in tandem to evaporate the water for a thoroughly dry product.

A dry screw vacuum pump is often used for high vacuum applications of vacuum drying. The vacuum pump draws high levels of vacuum pressure, evacuating the chamber and beginning the drying process. Before water vapor enters the pump, it enters a condenser to be collected and either recycled or properly discarded. This is most common with dehydrated foods, as well as pharmaceutical and chemical powders.

Advantages of Dry Screw Vacuum Pumps

The dry screw vacuum pump reaches far beyond the required ultimate vacuum level for vacuum drying applications. This means it can operate at much lower RPM, extending its service life and reducing need for maintenance and repair. There is no working fluid to maintain or change with the dry screw vacuum pump, meaning it is not held by the limitations of a working fluid’s vapor pressure. There is no risk of oil contamination, no expenses wasted by treatment and disposal of working fluid, and easy purging. The gas purge is simple and the cleaning of the pump is just the same.

The dry screw is of robust design and is capable of pumping harsh process gasses with the proper corrosion-resistant metallurgy. The design can be configured with variable frequency to address energy saving concerns, cutting costs and lessening the environmental impact of the pump. The dry screw vacuum pump boasts a high capacity to power ratio, boosting efficiency and cutting down operation costs even further.

NES Company Inc. is proud to offer the NSP Series double screw dry vacuum pumps. The NSP Series is capable of achieving vacuum levels that are orders of magnitude higher than the recommended ultimate vacuum level used in the drying process. NES Company Inc. offers corrosion-resistant metallurgy for harsh process gasses and several accessory kits such as gas ballast and exhaust silencer kits for the perfect dry screw vacuum pump setup, particularly suited for any industry and application. Spare parts kits are also offered, making DIY maintenance and simple repairs even quicker of a process. Contact us to ask about our competitive prices with a wide array of optional accessories and compatibility with major dry screw series models like MD Kinney SDV, KDP; Nash VSB; Edwards GXS; Leybold DV; Busch NC, NF, NS, NX, BA, BC, DS; Flowserve SIHI S, V; Quincy QSV; and Elmo Rietchle VSB, VSI Series.