Refrigeration and Cooling

Refrigeration has been a historically reliable method of preservation for millennia. By introducing and storing organic material in and to low temperatures, the growth and reproduction of certain detrimental microorganisms is discouraged and the decay rate of the material is drastically stunted. By introducing vacuum technology into this principle to create evaporative cooling, or vacuum refrigeration, the process becomes quicker, easier, and higher quality.

Relevant Applications

- Agriculture

- Sugar

- Tobacco

- Food

- Beverage

- Cheesemaking

- Edible Oil

- Laboratory

- Medical Health Services

Vacuum refrigeration is the process by which vacuum is used to flash-cool products of organic origin, such as produce, processed foods, distributed dairy goods, and high-water content liquids for storage or further processing. A vacuum pump is connected to a condenser and cooling chamber where the product batch is loaded. Plantation and farm products retain moisture from their growth; this spans anywhere from cattle to cabbage. Once the load is in, the pump begins to evacuate the chamber. Lowering the pressure within the chamber lowers the boiling point of the water held within the products as the atmospheric pressure supports the liquid’s intermolecular forces to hold it in its phase. The result is that the water evaporates at a much lower temperature than that in atmospheric pressure conditions.

When the chamber is held at a constant temperature and the pressure is lowered by the vacuum pump, the latent heat held within the batch is used by the water to evaporate, resulting in a batch of products that is significantly lower temperature than it was at entry into the chamber. Water in particular has a relatively high boiling point compared to many other solvents. Thus, for large batches or operating for longer periods of time, utilizing a vacuum pump and manipulating the pressure and boiling point is more efficient than lowering the temperature of the chamber via a heat exchanger at atmospheric pressure.

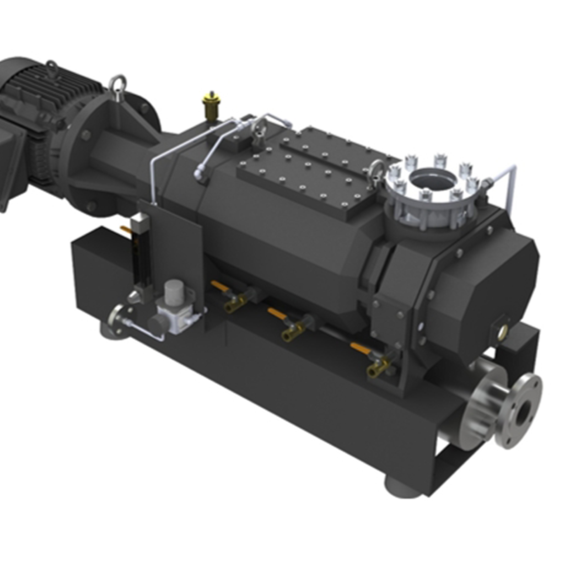

NES Company Inc. is proud to offer our NSP Series dry twin screw vacuum pumps. Offered with the pumps are optional kits, such as gas ballast kits and exhaust silencer kits, so that each industry and application can have an NES dry screw vacuum pump that is tailor-made and specialized for its intended function. NES Company Inc. also offer spare parts kits so that DIY simple repairs can be even smoother of a process, cutting downtime and boosting efficiency, all at our competitive pricing. We at NES Company Inc. place importance on timing and efficiency, and we are more than happy to prove this with our NSP Series dry screw vacuum pumps.