Liquid Ring Vacuum Pump for Waste Water / Municipalities

Because of the sheer number and population of factories and cities, wastewater containing chemical cleaners and biological waste cannot be naturally processed if we were to just leave it be. Sewage and chemical waste collects more and more as nature struggles to re-implement these compounds to the earth. Thus, modern society has implemented sewage piping, pumping stations, and treatment facilities, all of which use a liquid ring vacuum pump to effectively handle this septic and hazardous material.

First, wastewater and stormwater run through the sewer system. The water is screened for large debris, such as sticks, rags, and litter. This is to prevent unnecessary damage to the pipes, and the debris goes to a landfill. The remaining wastewater is pumped to a grit chamber to remove sediment. In the grit chamber, the flow rate is slower.

The heavier sediment sinks to the bottom of the chamber and the floating sediments, like grease or small plastics, are skimmed off. The bottom of the tanks are removed and pumped elsewhere for digestion while the remaining wastewater, just water and organic matter, is pumped away. The water is run through a clarifier, which mixes chemicals like polyelectrolytes and ferrous sulfate into the water. These bond with the remaining sediment in the water and cause it to fall to the bottom of the clarifier, where the sediment is extracted. Now, the wastewater is liquid and broken down organic matter. The speed of the flow is very important here. Too fast, and nothing will be clean. Too slow, and it will affect the process farther down the pipeline.

The next step is the aeration tank, where oxygen is pumped in to promote the growth of microorganisms that aerobically digest the remaining organic material into cell tissue, water, and nitrogen. The remaining waste, and any excess bacteria, is filtered through another sedimentation tank, and the water is sent to chemical treatment, like chlorination. Chlorine creates hydrochloric acid within the water and bonds with the membranes of waterborne bacteria, acting as an inexpensive sanitizer for the water. After the treatment, the water is tested for pH, percent of dissolved oxygen per unit volume, ammonia, and nitrate to match the permit level. It is then released into local waterways, like rivers.

Besides wastewater purification, municipal applications for vacuum pumps extend upstream to water sourcing. Municipal water sourcing includes purification of groundwater. Underground resources are readily available, but deep underground in an environment that lacks oxygen. For previously oxygen-deprived underground water sources that are discovered and used communally, aeration is important. Aerating the water will cause a chemical reaction between the atmospheric oxygen and any iron, manganese, and ammonium that may be present in the water. These molecules within the water cause a metallic taste or potentially unsafe consumption. The oxygen reacts with these in a way that the products are insoluble and heavier than water. It can then sink to the bottom of the water and be extracted. The result is cleaner, clearer water that tastes and smells better. It is more palatable and safer to consume.

Applications of Liquid Ring Vacuum Pumps

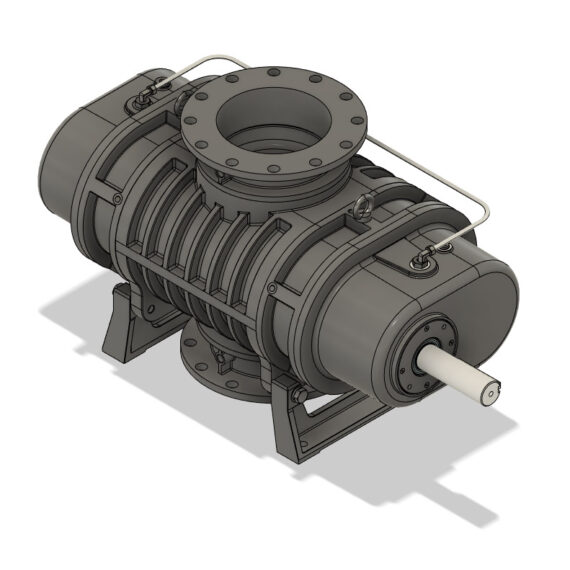

The applications for a liquid ring vacuum pump in this process are multiple. The pump is used for pumping the wastewater because it is better at pumping slurry-like substances than other pumps. Any particulate matter, slugs of water, or sludge will pass through without issue or damage. After selecting a proper material for pump construction, it is able to resist corrosion from any acidic or caustic chemical substances within the wastewater. Gasses dissolved in the wastewater, like methane and ammonia, cannot escape the pump, and it pumps both the wastewater and the gasses it contains at the same time.

This pump is particularly useful in wet and dirty environments because it utilizes a liquid ring and there is no moving metal-to-metal contact within the pump, so there is no concern of excess heat and friction from the pump itself affecting the material being pumped. Excess heat may cause concern for an explosive gas like methane, so the near-isothermal process of the liquid ring vacuum pump is a safer choice to use for this application. This is a beneficial trait not only for transporting, but throughout the entirety of the process, from the grit chamber to the sedimentation tank, and through the aeration tanks as well. Liquid ring pumps can also be used to control the amount of oxygen in the aeration tanks to encourage microorganism reproduction within the tank, as some microorganisms thrive in oxygen-rich environments while others thrive through anaerobic digestion. Because the survival and reproduction of the microorganisms is so important to the process of wastewater treatment, the precise control of a constant flow of oxygen is a necessity. The right kind of liquid vacuum pump for this application provides constant flow, explosion protection, precise control, resistance to corrosion, and increased efficiency in wet processes with condensable vapors.

Municipal Application

The liquid ring vacuum pump is suitable for wet processes and can handle liquid and gas transfer simultaneously. Bubbling or aerating groundwater delivers oxygen toward a wet application, a water source. As is the case, any moisture that is suspended as a gas around the water will negatively affect the moisture-sensitive dry-running vacuum pumps. A wet-running pump is needed.