The NES Perspective: Aerospace Manufacturing Vacuum Pumps and Compressors

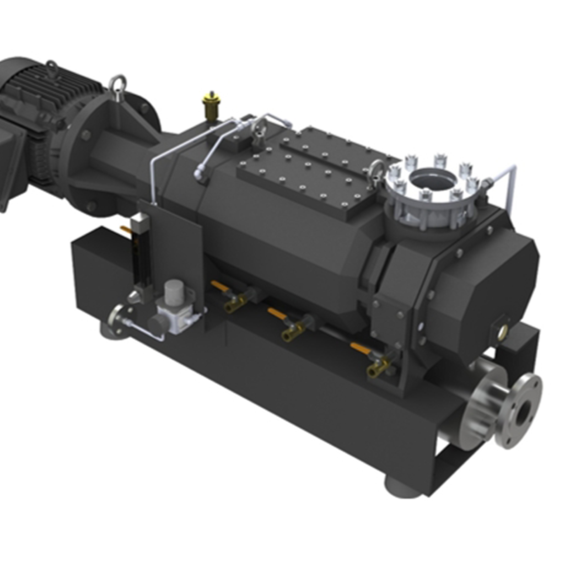

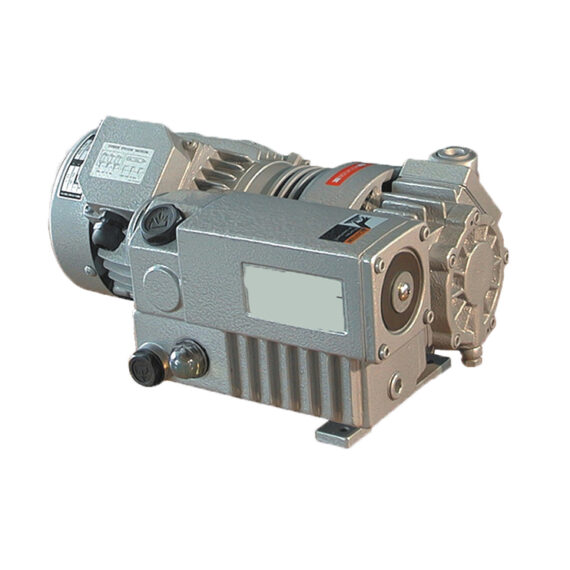

Aerospace manufacturing uses precise pressure control for processes like composite curing, heat treating alloys, and precision forming. Through these means, the industry can adhere to strict regulations on structural integrity and material properties.

- Adsorption

- Altitude Chambers

- Bag Lamination and Pressing

- Heat Treatment

- Furnaces and Ovens

- Wind Tunnels

Aerospace part manufacturing demands exact control over the system conditions to match the stringent industry standards. High-purity metals and alloys must be melted and reshaped to take the forms that are needed. However, atmospheric impurities like hydrogen and nitrogen can dissolve into the metal and create voids: small bubbles that tend towards grain boundaries in the metal, making the resulting product brittle and non-malleable.

With all the turbulence and vast pressure differentials that aerospace products undergo, it is extremely important that the parts are malleable enough to elastically deform under such stresses instead of snapping and cracking. Thus, various apparatus such as vacuum induction melting furnaces have been developed. Deep vacuum is induced on the chamber in which the metal is melting, keeping atmospheric impurities out and maintaining the structural integrity so desired by the metal.

From here, vacuum furnaces are used for heat treatment. The metal is softened, and dissolved gasses are drawn out. Oxidation and decarburization are not an issue anymore as processes like stress-relieving or age-hardening take place. Conventional heat treatment ovens can be used, but will not reach the quality and standardization that a vacuum furnace achieves.

Composites are on the other end of material sourcing, fabricated through vacuum bag lamination and pressing. Carbon fiber or fiberglass are commonly used in this process, pre-impregnated with resin or other chemical agent to ensure structure and weather resistance. These materials are laid into molds within a vacuum bag. As the bag is evacuated, the pressure inside becomes much lower than that of atmosphere. As a result, atmospheric pressure is applied all around the bag, pushing the resin to distribute evenly across the fiber. Sometimes several layers of fiber are laid into the bag and pressed together as the resin solidifies, resulting in a dense composite material that can withstand the force of flight and propulsion.

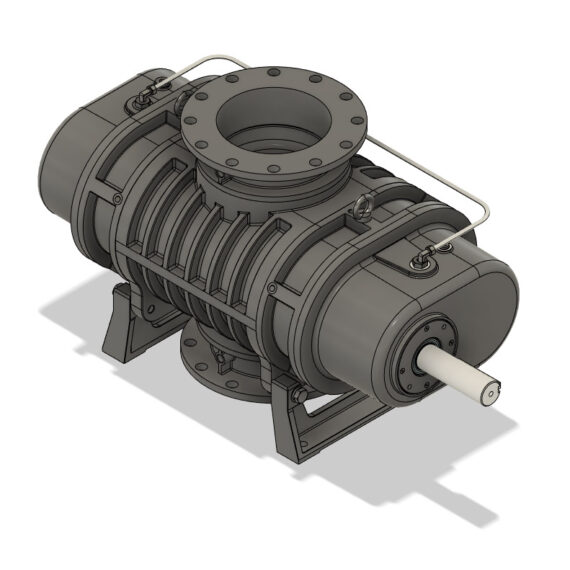

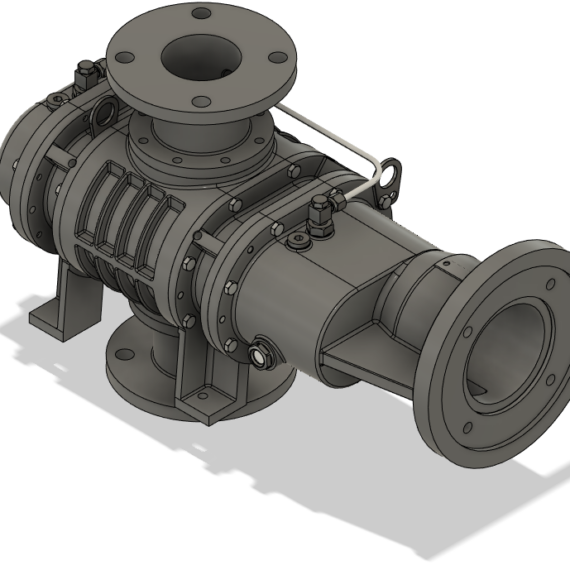

After the parts are manufactured, they must be tested. Select parts are tested using altitude chambers, which simulate the pressure and temperature conditions of specified altitudes that the part will be able to withstand. This is particularly important because up until now, the parts being considered have been applicable to end products like airfoils, blades, and cabins, but when it comes to equipment like fuel tanks, oxygen storage, and measurement devices, the need for testing the capabilities of operation in high-altitude conditions is absolutely necessary.

Along with high-altitude conditions, equipment must be tested for capabilities of operation in motion: aerospace parts must be aerodynamic. This is the role of the wind tunnel: testing the aerodynamic characteristics of aerospace parts before they are put into use and, most of the time, before they are even constructed. In this way, engineers can fine-tune laminar flow, pressure distribution and control-surface effectiveness on scale-models, yielding efficient and quiet aircraft.

From ingot and fiber to precision-engineered flight equipment and devices, vacuum and compression is found in each step to remove impurities, refine materials, and ensure comfort and efficiency. NES helps manufacturers push the boundaries of performance, safety, and sustainability.