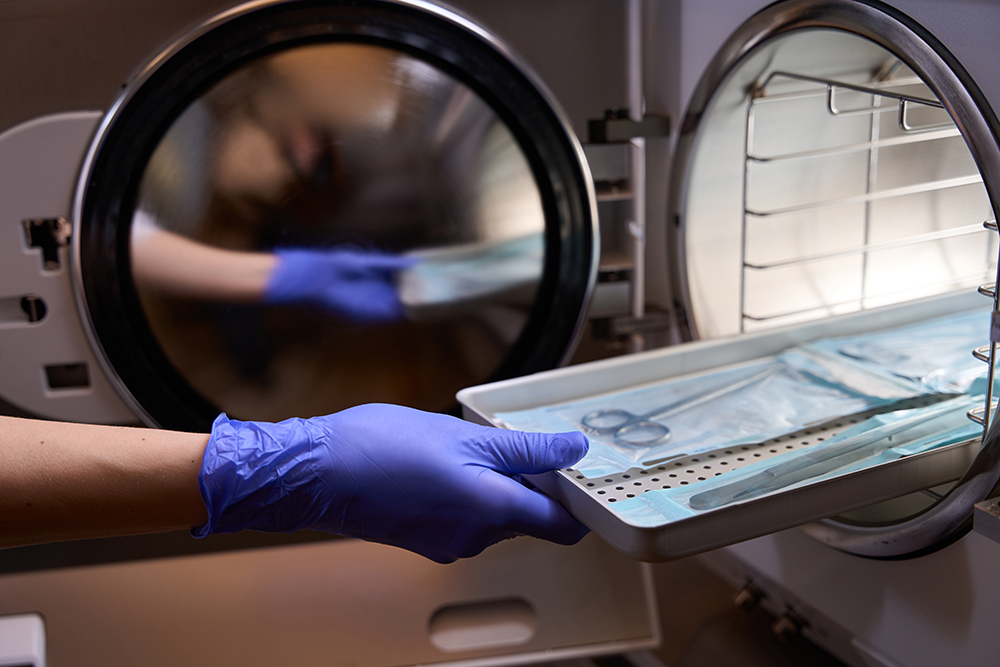

Autoclaves and Steam Sterilization

Autoclaves: Vessels that make use of sanitation methods and pressure manipulation in order to sterilize reusable tools and equipment.

Steam Sterilization: The process by which hot steam is used to eliminate microbial growth on reusable tools and equipment.

When producing staff or equipment that is intended for exposure to low-oxygen conditions at heightened elevations, it is important that testing be performed in simulated atmosphere. Altitude chambers, or hypoxic chambers, are employed to provide such a simulation.

Professionals such as military members or pilots who are required to maintain constant exposure to high altitudes must undergo training in hypoxic chambers to become adapted to the lack of oxygen. This influences their physical and mental composition such that they are prepared for the difficult environment that necessitates such training.

Flight equipment is also tested in hypoxic chambers to observe the effects of such environmental conditions on the physical attributes of the equipment. The lowered pressure and temperature, as well as the lower oxygen levels, may have influence on the structural integrity and accuracy of measurement devices and controls for aeronautic vehicles.

Professional athletes also train in altitude chambers in order to become accustomed to situations in which there is a lack of oxygen. When performing continuous anaerobic exercise in sports such as boxing or cycling in a given season, the athlete grows to become levelheaded and continues to perform exceptionally when running out of breath. Studies have shown that the body of an athlete will adapt to take in more oxygen per breath when exposed to continuous training in altitude chambers.

View our Products

NC Series

The NC Series liquid ring vacuum pumps are single stage, single cone pumps that are capable of up to 3200 CFM and 28” Hg of vacuum. The compressors in this series are capable of reaching up to 25 psig of pressure. These models feature high liquid carryover tolerance due to the conical lobe design, self-priming capability, side discharge to minimize flooding risk, and optional mechanical seal installation. These vacuum pumps and compressors come in many different materials, including cast iron and stainless steel 304 or 316. Conical lobe liquid ring vacuum pumps and compressors are especially tolerant of contaminants and slugs of liquid, which comes in handy when processing hair, dust, or condensing steam. Dry-running vacuum pumps and compressors would potentially face catastrophic failure if exposed to the steam or dust, but liquid ring technology simply passes these through without issue.