Barge Loading and Unloading

The displacement of bulk goods onto and off of barges for maritime transport.

When moving small product in bulk, such as powders and granules, using a vacuum pump or blower to move the product is effective and efficient. Through long stretches of piping and a conveying system, barges can be unloaded quickly into silos that are then emptied onto trucks for distribution.

It is important to consider the particle size, moisture content, bulk density, and desired path when sizing and designing a conveying system. Some products, particularly ones in agriculture, are washed in pre-processing before storage and shipping, so they carry significant moisture content through the conveying system. Some powders, such as chemical powders or metal powders, must not make contact with moisture at all.

Vacuum conveying systems are particularly beneficial when processing bulk product from multiple sources. Pressure conveying systems, on the other hand, are especially useful when distributing the bulk product to multiple locations. Some conveying systems feature both vacuum pumps and compressors in order to increase efficiency at the cost of increased maintenance and initial capital investment.

View our Products

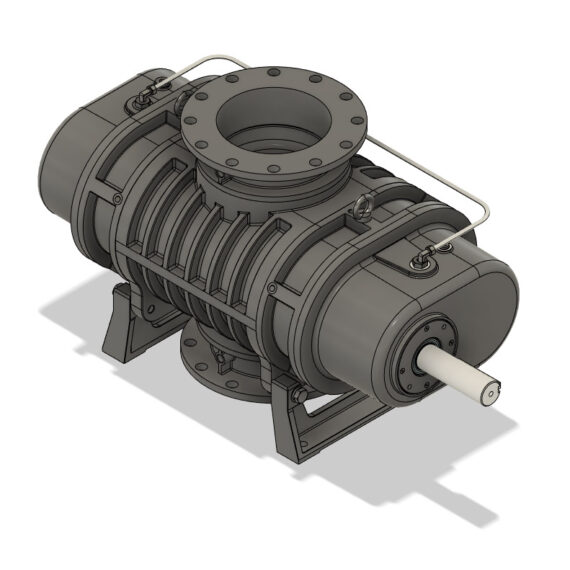

NRB Series

NES Company Inc. offers the NRB Roots-Type Rotary Lobe Blower as a solution to vacuum and pressure requirements for conveying systems. The NRB Series is capable of up to 17”Hg of vacuum and 15 psig in pressure, reaching a maximum capacity of 9280 CFM. These models feature a five-point bearing, double oil tank, synchronous gears, numerous mechanical seals available for selection, optional gas-tight design, and a one-year warranty against manufacturing defects. Roots-type blowers are energy-efficient, durable, low-maintenance, and quiet. They are able to function both as a standalone unit and as part of an engineered system, boosting the vacuum capabilities through the compression of process gas to the end of boosting capacity as well. NRB Series blowers are offered with a one-year warranty against manufacturing defects.

NSP Series

NES Company Inc. offers the NSP Dry Screw Vacuum Pump as a solution in both vacuum and pressure for conveying systems. This series achieves up to 1766 CFM with up to 0.0075 Torr in vacuum and up to five times atmosphere in compression. Dry screw vacuum pumps are able to pull vacuum through the inlet, simultaneously providing compression at the outlet due to the variable pitch of the NSP screw rotors. The pitch allows for even distribution of compression throughout the length of the body, preventing uneven stresses from damaging the pump. Dry screw vacuum pumps are among the most efficient in terms of capacity per unit power and offers zero process contamination because it does not require oil or other lubrication to come into contact with the process. NSP Series pumps are available with optional kits and accessories such as gas ballast kits, repair kits, inlet purge kits, and solvent flush kits that are employed to lengthen pump life and improve performance. NES Company Inc. offers a one-year warranty against manufacturing defects.

NC Series

NES Company Inc. NC Series single stage, single cone liquid ring vacuum pumps and compressors are a widespread solution for vacuum and pressure conveying systems in the United States. As a drop-in replacement of Nash Classic SC Series vacuum pumps and compressors, the NC Series is exceptionally tolerant of liquid carryover and stray particulates. This series reaches up to 3200 CFM, 28”Hg of vacuum, and 25 psig in pressure. Flecks of dust and dirt will not affect the performance of the pump or compressor as they do to dry-running vacuum pumps or compressors. Moisture is passed through liquid ring technology with little effort and minimal effect on pump performance. NC Series vacuum pumps and compressors are offered as a bare pump or compressor, or as part of an engineered system with a two-year warranty against manufacturing defects.