Condenser Priming & Exhaust

The process by which vacuum is used to create optimal conditions for a condenser to perform exceptionally.

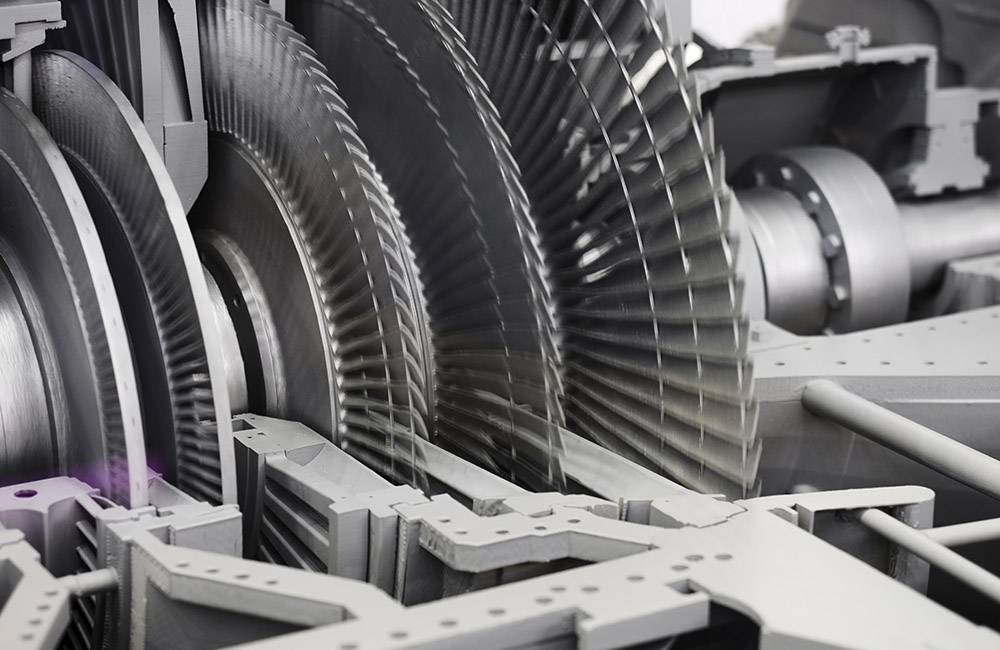

In each steam-generating power plant, there exists four essential elements: a heat source, a turbine, a feedwater pump, and a condenser. The condenser collects the waste steam and condensate from the turbine after it has been used (and possibly recycled), ensuring complete condensation via heat transfer and guiding the condensate to either a treatment facility or through a recycle loop to the heat source. These condensers are not just found in power plants; anywhere that a condensable vapor is used and captured for reuse, a condenser will be found. This includes distillation columns, steam cracking units, and much more.

View our Products

NCC Series

The NCC Series is perfect for condenser priming because of its compact size and long service life. With proper maintenance and care, we have seen NCC Series models last for decades with consistent performance. With a maximum capacity of 350 CFM and vacuum capabilities up to 28”HgV, the NCC Series is our recommendation for the labor required of a condenser priming vacuum system. This series is covered by a two-year warranty against manufacturing defects.

A condenser consists of a cylindrical casing held on both ends by waterboxes. Waterboxes store and allow for the pressurized flow of water into the condenser via the condenser’s tube sheet and bundle so the vapor can condense. The water must be drawn into the waterboxes via centrifugal pump, but centrifugal pumps are empty upon startup and usually are not designed to prime themselves. Thus, a vacuum pump is used to evacuate the air from the centrifugal pump, as well as drawing a column of water into the centrifugal pump so that it can start. From there, the centrifugal pump pressurizes and sends water into the waterboxes, where they are guided through hundreds of small pipes that run across the condenser from waterbox to waterbox. Without the vacuum pump, the non-self-priming centrifugal pump will not run. Without the centrifugal pump, the waterboxes lack the required cooling water to properly uphold plant efficiency. A waterbox that is not working at full operating capacity will result in significant energy efficiency losses, summing up to tens or even hundreds of thousands of dollars annually in such large-scale operations.

Besides the waterboxes, a condenser also has a vacuum pump that takes care of exhaust. The purpose of a condenser is to take in condensables and guide them, once fully condensed into liquid, towards some kind of treatment or pressurizing station. The presence of gas in the liquid stream prevents the downstream equipment from operating effectively. Thus, a vacuum is pulled on the condenser chamber itself. Not only does this help the condensable vapor to liquefy by lowering the temperature, but it also degasses the resulting liquid, making the entire process much more efficient.