Condenser Priming

The process by which a piece of equipment is used to create optimal conditions for a condenser to function within expected, calculated or otherwise desired parameters.

The waterbox is part of many liquid circulation systems. Its job is to regulate the flow of liquid in it and to store some of the liquid. Waterbox pumps, like centrifugal pumps, are designed to be submersible pumps and have difficulty pumping gas.

In addition, pumping gas instead of liquid would decrease the mass flow rate of the liquid, decreasing efficiency. Nevertheless, gas remains in the waterboxes and circulation systems in the form of ambient air and dissolved gasses in the liquid. Really, anywhere that liquid is pumped from a lower level to a higher level, there will be a need for a priming system. In this priming system, the appropriate pump is used in tandem with a priming valve. This pump is able to draw gas out from the circulation system.

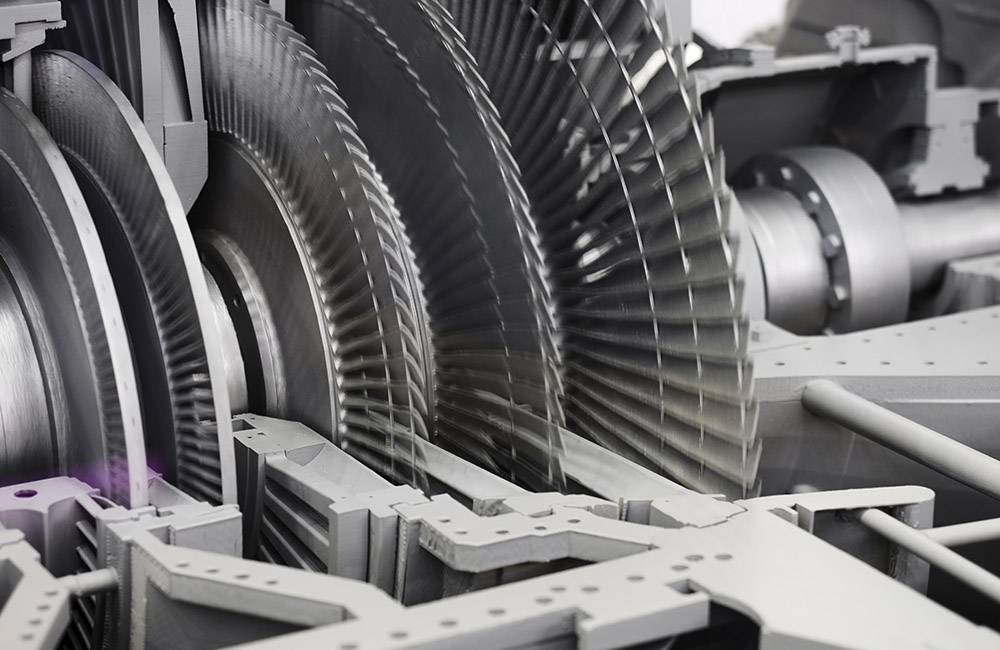

The priming valve contains a float which sinks down, opening the valve for suction from the pump. As the liquid level in the system rises up the priming valve, the float rises as well, eventually sealing the suction point. At this point, there is an insignificant level of gas in the system. The submersible pump, such as a centrifugal pump, is turned on. The water is then properly circulated without hindrance from gas in the system. This translates to better circulation of cooling water in steam turbine condenser systems, more efficient pumping with less slugs of water in clean water pumping as well as wastewater pumping, and the myriad other applications that a waterbox can fit into.

In 2018, the Shin Boryeong Thermal Power Plant reached new levels of thermal efficiency in their power generation through use of vacuum pumping systems. One of these systems included two separated vacuum systems designated solely to priming the condenser waterbox. The idea is that air will heat up much more quickly than water so it needs to be removed from the condenser waterbox to obtain even higher thermal efficiencies. In this way, vacuum systems push condenser priming toward the future.

View our Products

NCC Series

The NCC Series is perfect for condenser priming because of its compact size and long service life. With proper maintenance and care, we have seen NCC Series models last for decades with consistent performance. With a maximum capacity of 350 CFM and vacuum capabilities up to 28”HgV, the NCC Series is our recommendation for the labor required of a condenser priming vacuum system. This series is covered by a two-year warranty against manufacturing defects.