The NES Perspective: The Industry of Aquaculture

Aquaculture depends daily on pressure control for everything from water circulation to waste removal. Adding pressure equipment ensures the stability of aquatic environments and efficient harvest handling from hatchery to distribution.

- Aeration

- Filtration

- Conveying

- Packaging

Aquaculture is the farming of aquatic organisms like fish and seaweed. Although this is an industry that takes many forms across the world with traditional techniques developed according to the particular species being farmed, large-scale aquaculture often takes advantage of modern technology to make procedures more efficient and healthier for the organisms that make the industry.

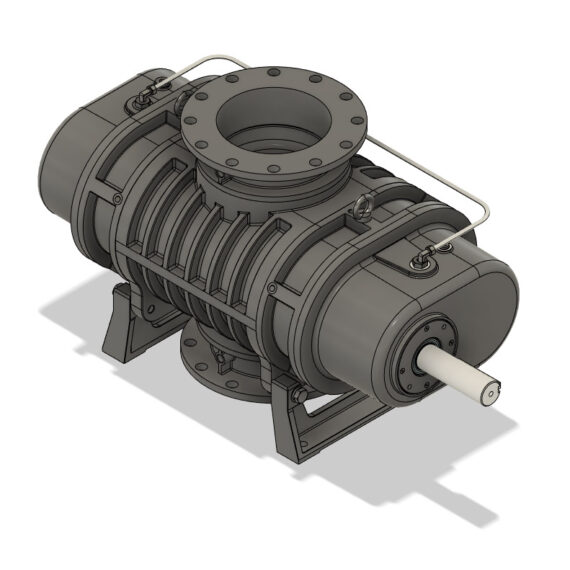

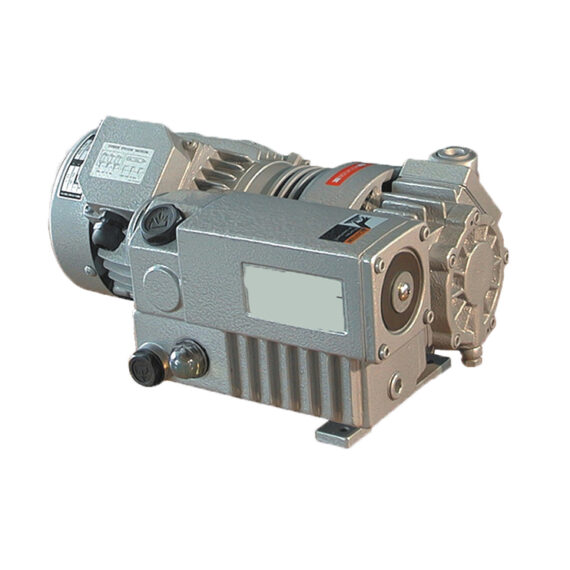

At the heart of aquaculture is water quality. Aeration and oxygenation systems powered by compressors or blowers evenly distribute oxygen to tanks and enclosures. Vacuum-assisted filtration and solids removal elements aid in eliminating suspended waste, deteriorating feed, and metabolic byproducts to maintain a stable ecosystem.

As the fish mature, they must be transported quickly and gently to larger enclosures. Pneumatic conveying is often favored as it utilizes forced air pressure differentials to influence the flow of fish through closed pipes, reducing manual labor while providing a soft, rapid ride for the fish. Dewatering systems are put in place for precise water removal when transferring stock. The water is either sent to drain or the filtration elements, quickly taking care of any potential for unwanted biological growth.

Once harvested, the animals are sorted by size or species using automated grading systems. In the case that the livestock are to be sent for preparation and packing, the product is tightly packaged in airtight packaging that is vacuum-sealed to preserve freshness, hinder aerobic bacterial growth, and keep out airborne microorganisms that could feed on the product and cause decay. This extends shelf life and maintains both appearance and quality.

From hatching to shipping, these pressure and vacuum systems are vital to the operation as a whole. Having such an automated system that increases production output while contributing to more sustainable and humane farming practices is a must in a world that continues to progress both in technology and responsibility towards the environment. As the industry grows to accommodate global food demands, efficient and reliable pressure technologies continue to be indispensable partners to every successful operation.