Coating, Deposition, and Metallizing

The atomization and uniform distribution of a material over another to impart an outermost layer that exhibits the desired physical or chemical properties.

View our Products

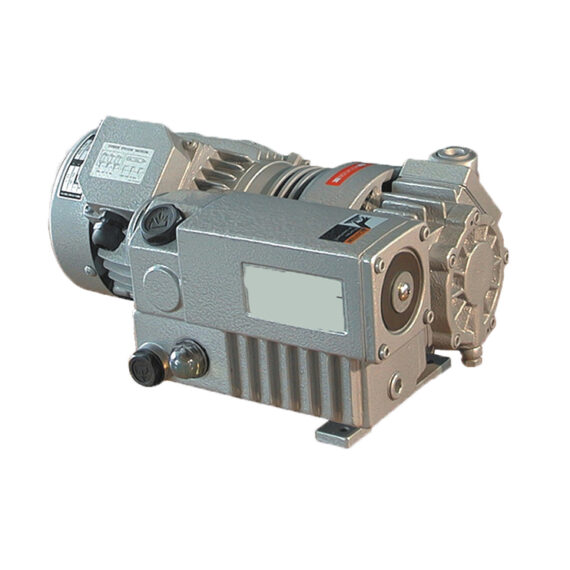

NRV Series

An oil-circulated rotary vane vacuum pump is used as a roughing pump for an ultrahigh vacuum pump like an oil diffusion pump to evacuate the deposition chamber for vacuum deposition. Operating such a deep vacuum generating apparatus on its own without a roughing pump will cause it to require maintenance, repair, or replacement at an accelerated rate. Maintenance and repair are more difficult because of the complex design of the diffusion pump. Overexerting the ultrahigh vacuum pump or increasing its operating time will result in more frequent repair or replacement. The rotary vane vacuum pump, contrary to the ultrahigh vacuum pumps, is very simple in design with few moving parts. It is extremely simple to maintain and repair. If it needs replacement, it is of little issue, as rotary vane vacuum pumps have long been one of the most inexpensive pumps on the market. NES Company Inc. offers the robust and reliable NRV Series single stage oil-circulated rotary vane vacuum pumps, as well as accessory kits and spare parts kits for a smooth repair process. The accessory kits are selected for specialization to be tailor-made for intended use in the industry.

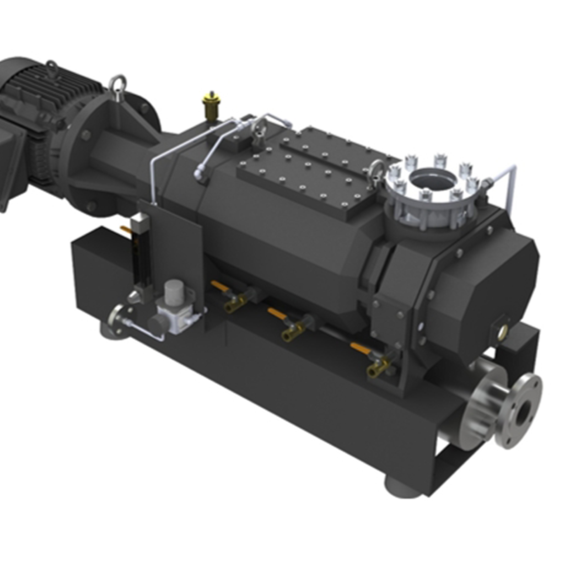

NSP Series

For medium-sized production coating processes that require deep levels of vacuum, NES Company Inc. offers the NSP Series dry screw vacuum pumps. As a standalone unit, they are able to reach high levels of vacuum through extremely energy-efficient means thanks to the meticulous design brought about only recently in the vacuum world. This means that without any forepump or backing pump, the NSP Series is able to provide all of the suction and vacuum that is required of these deposition processes.

Coating covers a family tree of methods, techniques, and know-how that applies differently depending on industry, material, product, and location. Thermal methods, mechanical methods, chemical methods; vacuum methods, atmospheric methods, and pressure methods are all mixed and matched to yield a perfect product.

Coating itself is an umbrella term that encompasses applying a layer onto a surface in all ways. Among the methods of coating is vacuum coating, yet another umbrella term – albeit a bit finer – that discusses the application of a layer onto a surface under vacuum conditions for the benefits that negative pressure provides. The most widespread of the various subcategories of vacuum coating is vacuum deposition.

Vacuum deposition is the process of delivering atoms or molecules to a surface under vacuum. While other vacuum coating methods may apply broad strokes, deposition is specifically the undertaking of building an even coating of a material, one atomic or molecular layer at a time. There are two main types of vacuum-assisted deposition: physical vapor deposition (PVD) and chemical vapor deposition (CVD).

PVD encapsulates sputtering, plasma, and many other deposition techniques. This deposition category relies on about Torr (absolute) in vacuum to alter the behavior of matter at a molecular level. While the different raw material and apparatus are unique in every specific PVD method, the beginning is in the physical vaporization of solid material. Thermal evaporation, electron beam heating, or ion sputtering ensure that the target is evenly ejected onto the substrate. As the ejected atom arrives at the substrate, it becomes an adatom: an individual atom that is adsorbed onto the surface of a material, but not yet incorporated into the material. Through careful manipulation of surface temperature, ion energy, and substrate material choice, the adatoms will behave predictably: island growth (clusters), epitaxial (layer by layer), or mixed. Increasing ion density yields denser, smoother, harder films for optics, cutting tools, microelectronics, and more.

The priority of consistent vacuum in PVD comes from two considerations: lower pressure ensures easier vaporization, and lower pressure ensures straight line paths for ballistic transport. A lower pressure within the chamber allows atoms from the solid material to decompress from one another, making it easier for an ion source to eject an atom from the target onto the substrate. As the atom is being ejected, it is important that it does not collide with suspended particulate or atmospheric make-up – this part too, vacuum takes care of, evacuating the chamber such that there is no contamination which can disturb the straight-line flight of the ejected material onto the substrate. This pair of considerations is taken care of by the vacuum system, ensuring uniform layer distribution and lower energy expenses.

Vacuum metallizing is a subcategory of PVD which employs vacuum evaporation to apply metallic coatings on surfaces. Most commonly aluminum is deposited on plastic, film, or fabric. To begin, the chamber is evacuated to lower the boiling point of aluminum and eliminate the chance of atomic collision. Rather than metallizing with aluminum in atmospheric pressure, where the boiling point sits at about 2750 °C, vacuum metallizing is much more eco-friendly, cost-effective, and high-quality, providing nothing but benefits to the coating world.

CVD is also but a subcategory, containing within its definition a myriad of carefully designed operations. Gaseous precursors are introduced to a vacuum chamber with the substrate inside. The gas diffuses towards the substrate, adsorb onto the surface, and react chemically with the substrate itself, resulting in a solid film and some volatile byproducts which are effectively removed by the vacuum system. While the vacuum required is not as low as with PVD, it is still a considerable Torr, with some CVD methods requiring just the same ultra-high vacuum as PVD (UHV-CVD). Because of the way that the vacuum interacts with the precursors and the chemistry behind the deposition, CVD is able to coat complex three-dimensional geometries in a uniform manner.

As can be seen, coating is a rather large family tree of techniques across multiple industries around the globe. Throughout these methods, however, vacuum remains as a helping hand, if not an essential worker, to boost efficiency, cut costs, and go green for every lens and film produced.