Vacuum Drying Rotary Vane Vacuum Pumps & Compressors

Vacuum drying is extremely useful in multiple industries, from the manufacture of preserved food products to the dehydration of pharmaceutical powders for use as medicine. By manipulating the pressure around a product, batches and samples can be perfectly dried to a controlled and calculated moisture content.

Drying is the process of physically manipulating liquid in an absorbent solid to cause it to evaporate and leave the solid that it occupies. Drying can be useful in chemical laboratories, as some anhydrous compounds react in different ways than their hydrous counterparts. This can be used to the advantage of the industry depending on the desired result. Drying is useful in the leather, sugar, paper, tobacco, pharmaceutical, and food industries as well.

Vacuum drying is based on the physical principle that lowering the pressure of the ambient air around a liquid will lower its boiling point. The boiling point of a liquid is dependent on the vapor pressure of the liquid and the pressure of the air surrounding it. When liquid is heated, its temperature increases as the molecules of the liquid begin to gain energy, bumping into each other. The surrounding air exerts a pressure on the liquid that prevents it from evaporating.

At the temperature where the vapor pressure of the liquid is equal to the pressure of the surrounding air, the liquid begins to evaporate. This is because the liquid has gained enough energy to where the molecules are able to overcome their bonds to each other and release their energy by means of converting the excess heat energy into kinetic energy. This can be seen when the liquid begins to boil, and the temperature stagnates. When that pressure is decreased, the energy that is required to evaporate the liquid decreases.

Operation costs to dry batch products in atmospheric pressure can become staggeringly high. The manipulation of pressure to decrease the required heat energy for evaporation cuts operational costs significantly. Another benefit to vacuum drying is that the product can dry in the absence of oxygen, which can cause oxidation and decay to occur in numerous compounds. In addition to this, certain organic compounds are prone to degradation when exposed to excess heat. Water has a relatively high latent heat of vaporization, so the threat of degradation of heat-sensitive hydrated material. By applying negative pressure, the energy applied for evaporation cannot reach such levels of heat.

Applications of Liquid Ring Vacuum Pumps

Depending on the material to be dried, the temperature, pressure, and equipment vary. Some materials require a higher level of vacuum due to heat sensitivity or being hydrated with a solvent that has a higher latent heat of vaporization. Other materials will be damaged by higher levels of vacuum, or simply dry faster without strong levels of vacuum.

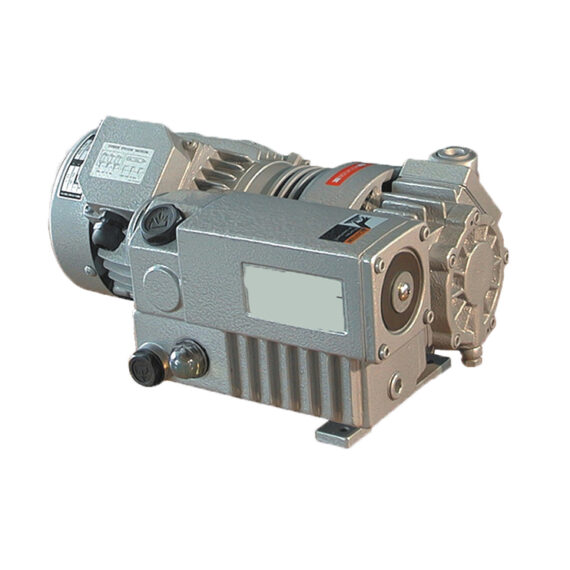

For medium vacuum applications, an oil-sealed rotary vane vacuum pump is connected to a solvent or cold trap that is further connected to the drying chamber. This prevents moisture from entering the pump, as it can be sensitive to more than trace amounts of moisture. The oil may emulsify with the water during operation and create a sludge that hinders pump performance.

Advantages of NES Vacuum Pumps

NES Company Inc. is proud to offer the NRV Series oil-flooded rotary vane vacuum pump. The NRV Series is perfect for low to medium level vacuum applications in drying. The series models are built with robust, simple design that makes for a long service life with simple maintenance and repair. The service life is only extended with the use of oil circulation, which acts as a lubricant between contacting parts and a barrier against any potentially oxidative gasses.

NES Company Inc. offers accessory kits and spare parts kits for simple DIY maintenance and repair, complete with competitive pricing for oil-flooded rotary vane vacuum pumps. The accessory kits can be selected to be specialized for your specific vacuum drying process.