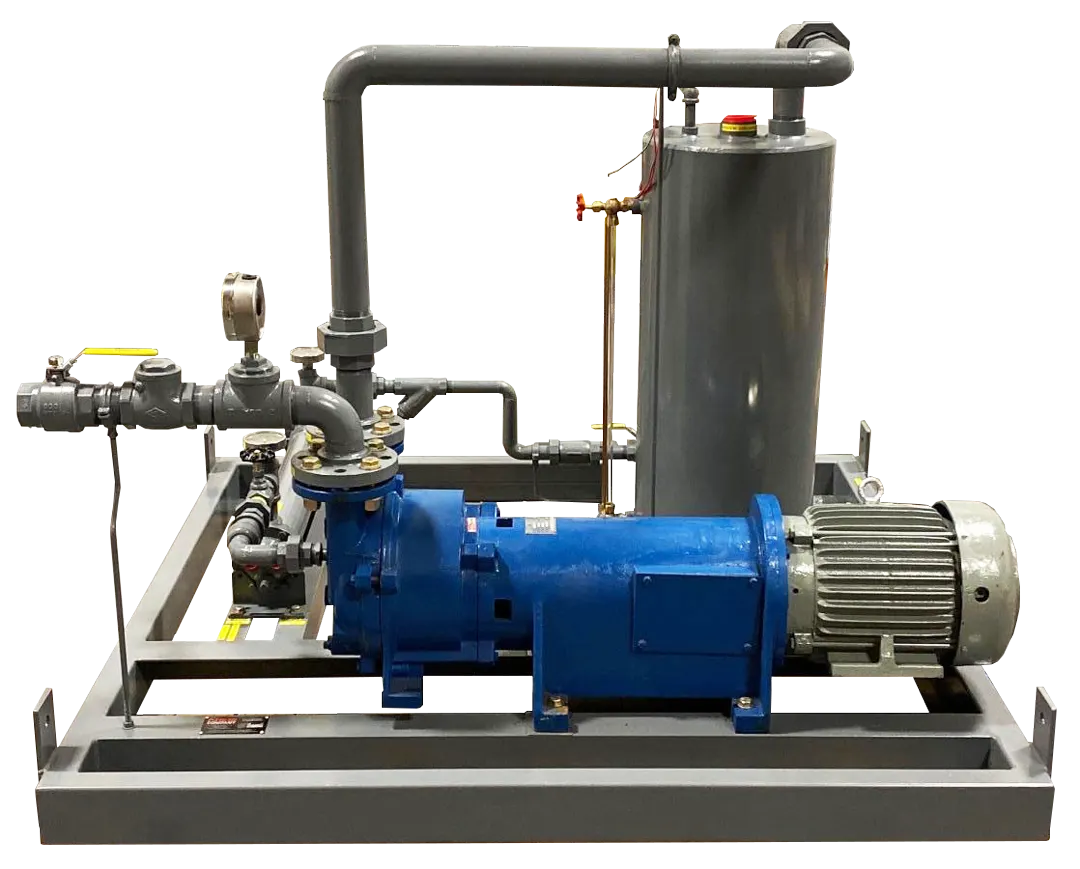

A customer approached us to build system around solvent recovery process. NES Engineers responded with a basic design for a full recovery system since water was not available at site. With severe duty Class I Div 2 7.5 HP motor the system designed has the capacity to deliver 110 CFM at 20 Inches of Mercury. The system has Stainless Steel 304 discharge separator with a shell and tube heat exchanger. The system has glycerin vacuum and temperature gauges to accurately displays process parameters. The piping is welded to prevent damage due to shipping and leaking. The base is box welded with lifting eyes and can be bolted on to the ground, making this easy to install. This was delivered in record time to ensure we meet customers deadlines.

Solvent Recovery System