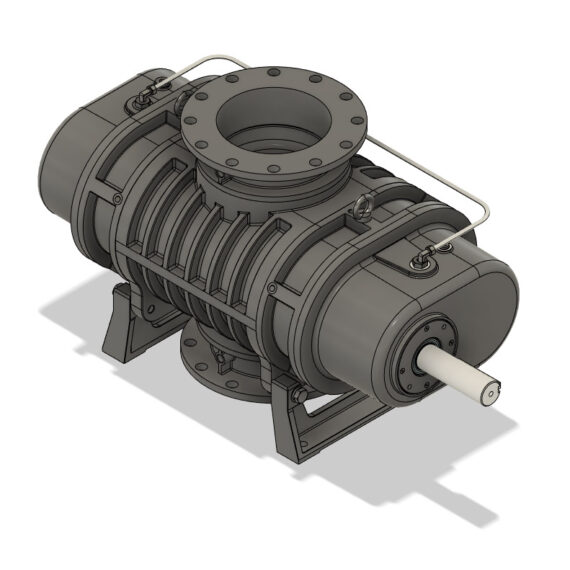

Liquid Ring Vacuum Pump for Waste Water / Municipalities

City infrastructure depends on the precision of pressure control to transform raw inputs into stable, reliable services. Whether refining groundwater or reclaiming low-grade heat, these systems rely on carefully shaped pressure gradients to guide chemical reactions, recover energy, and maintain steady delivery. The result is not just efficiency—it’s consistency, resilience, and public trust built into every tap and radiator.

City utilities lean on pressure control every day, whether they are keeping tap water clear or pushing heat through a district loop.

Raw groundwater often arrives with dissolved gases (H₂S, CO₂) and trace metals such as iron and manganese. Aeration towers or diffused-air basins feed a curtain of fine bubbles into the flow; the diffuser plate pore size and blower flow rate keep bubble size uniform, which in turn maximizes gas transfer. As the bubbles rise, hydrogen sulfide and carbon dioxide strip out, while iron and manganese oxidize to insoluble flakes that downstream filters remove. The payoff is cleaner taste, better odor control, and less staining inside household plumbing.

Low-pressure flash steam still carries useful enthalpy, but its temperature sits below the set-point needed for space heating. Mechanical vapor recompression (MVR) skids pull that steam, compress it to a higher pressure, and push it back into the supply header. Every step up in pressure raises the saturation temperature, letting the network recover heat that would otherwise vent to atmosphere. Fuel usage decreases, boilers cycle less, and the system holds a steadier delivery temperature through cold winters.

The common thread in municipal applications is tight management of calculated pressure gradients. With that in order, municipalities can cut energy costs, stretch existing assets, and deliver a cleaner, more reliable service to their citizens and residents.

Municipal Application

The liquid ring vacuum pump is suitable for wet processes and can handle liquid and gas transfer simultaneously. Bubbling or aerating groundwater delivers oxygen toward a wet application, a water source. As is the case, any moisture that is suspended as a gas around the water will negatively affect the moisture-sensitive dry-running vacuum pumps. A wet-running pump is needed.