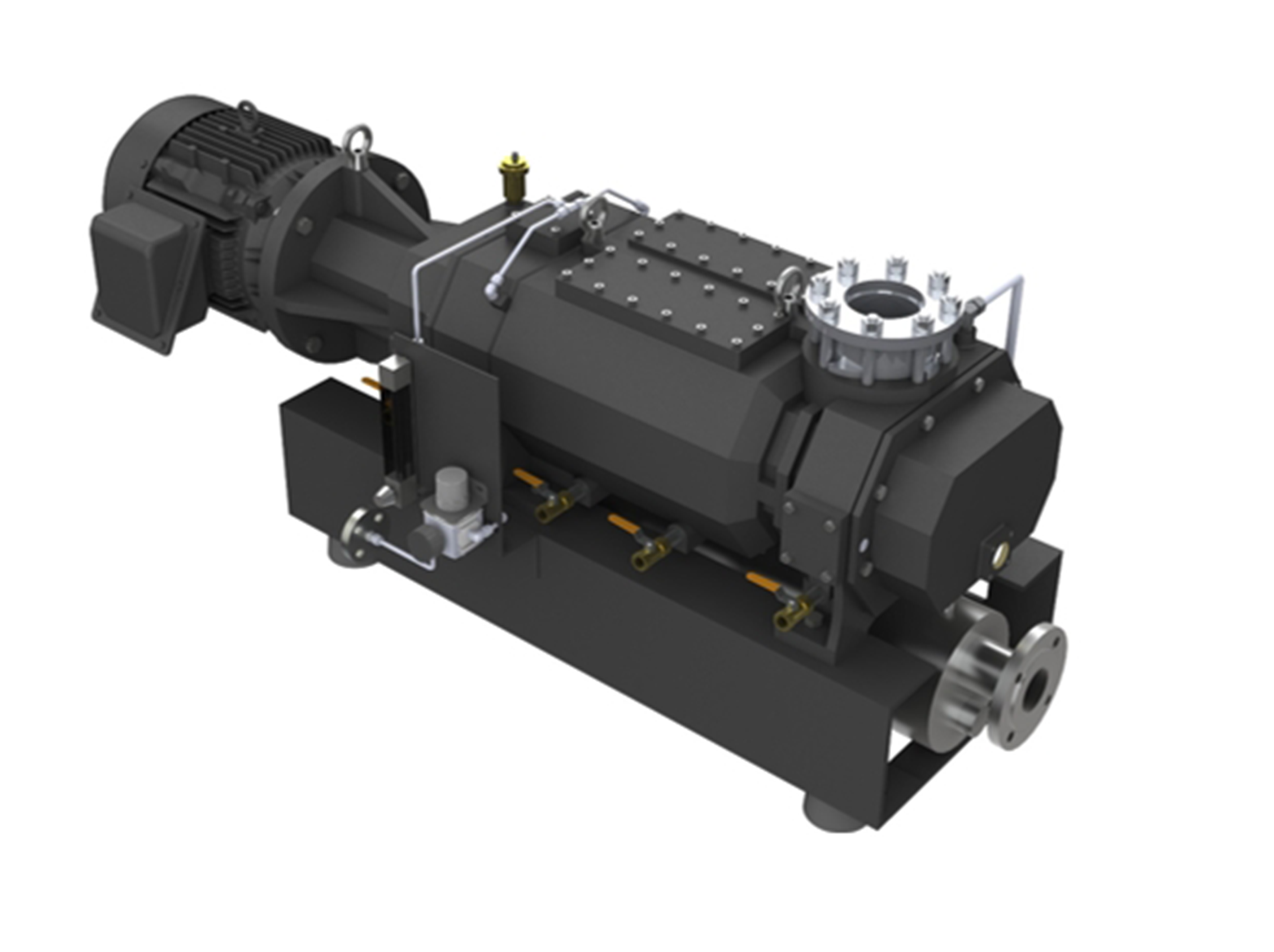

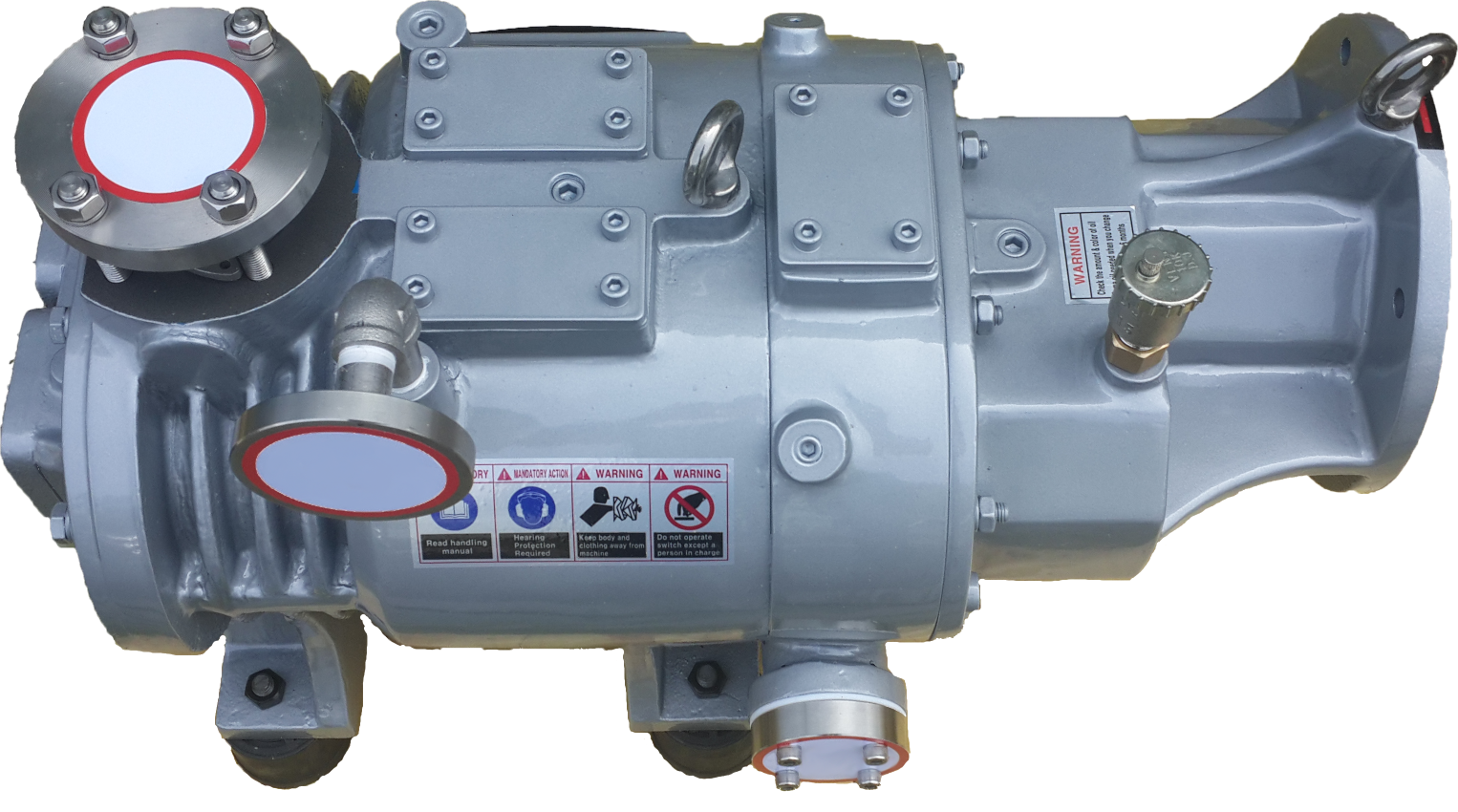

NSP Series – Dry Screw Vacuum Pumps

NSP series pumps are positive displacement, dry-running units designed to isolate the process material and deliver deep vacuum performance. They achieve ultimate vacuum levels down to 1 Pa, making them ideal for high-performance industrial applications. These pumps run completely dry—no sealing fluids enter the process chamber at any point during operation. Mechanical seals and oil lubrication remain fully isolated from the process flow to protect purity and prevent contamination. This makes NSP pumps ideal for clean processes and for handling toxic or highly corrosive gases in demanding environments.

Each unit uses two helical screw rotors that rotate in opposite directions to move gas axially through the pump. The rotors’ variable pitch compresses gas gradually throughout the body, unlike constant pitch designs that compress near the outlet. This improves thermal stability, reduces energy consumption, and ensures more efficient compression of process gases. Users can drive the pump via either a belt or direct coupling transmission, depending on system requirements. A gear system synchronizes the screws, creating a balanced, continuous motion that draws gas toward the outlet port. The versatility and reliability with which this pump carries its name pushes NES at the forefront of the modern market along with a 1-year warranty against manufacturing defects,

About NSP Series

Models: NSP-150, 300, 400, 600, 800, 1000, 1500, 2500, 3000

Features

Efficiency: The variable pitch screws lead to lower overall energy consumption by the pump system.

Zero Process Contamination: No contact between the process gas and any oil or water in the pump.

Simple Maintenance: Requires oil changes and inspections on regular, lengthy intervals.

Access to Parts: NES Company stands alone in the industry by offering spare parts for DIY repair.

Pressure ranges from atmospheric (760 torr) to 5 x 10-2 torr.

Versatility: Usable in a very wide range of industries with very different pumping needs.

Reliability under even the harshest pumping loads and conditions.