The NES Perspective: Cement & Lime Production

Cement and lime production rely on intense heat, precise airflow, and efficient material handling—functions made possible by blowers, compressors, and vacuum systems.

- Aeration

- Fluidization

- Handling, Conveying

- Packaging

View our Products

Cement production and lime production are separate processes that yield vastly different materials, yet the processes of production themselves follow a similar format: high-volume, high-temperature operations that keep the stream clean, continuous, and controlled. Vacuum pumps, blowers, and compressors are essential tools that simplify and enhance this format.

Cement production begins with crushed limestone, clay, and shale. The end product is a perfect mixture of components like these, as well as clinker and pozzolanic material like fly ash, so the components are carefully metered. The crushed constituents are dried and stored in silos until they are needed for production.

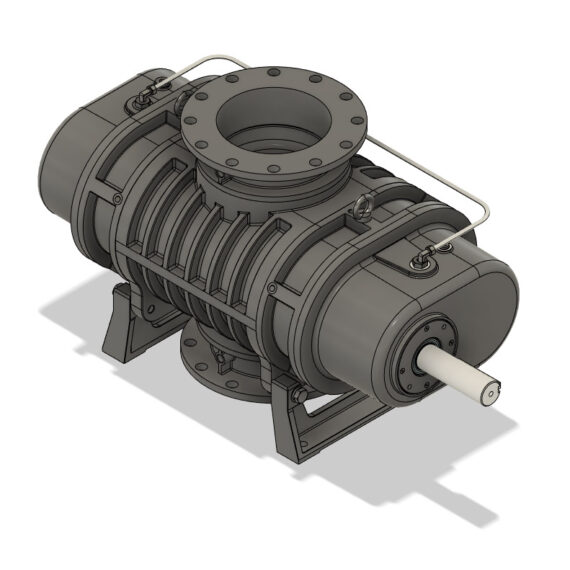

Once the time has come, blowers induce a fluidized state in the silo, allowing the components to flow at continuous rates. Rotary airlock valves are able to maintain the pressurized, fluidized state in the silo while offering precise metering capabilities for the measurement and contribution of each component to the final mix.

Blowers are also responsible for feeding a steady flow of oxygen to the combustion area and cool the resulting clinker. The cooling air carries an enormous amount of heat as the kiln heats the clinker up to 1450 degrees Celsius. The heat is guided to the limestone and clay that is entering the kiln. This conserves waste, and cuts costs on combustion reactants and required power.

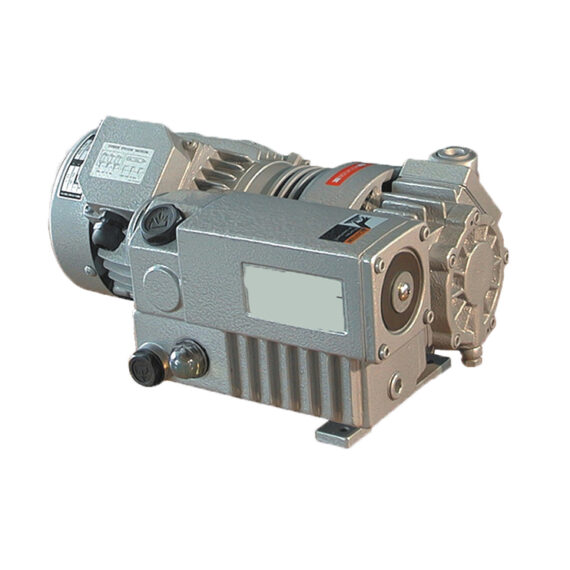

The clinker is ground into fine powder and pneumatically conveyed to be mixed with gypsum to control set time. Sometimes pozzolanic materials like fly ash are mixed in as well, reacting with the cement and water to form stronger bonds and yield a stronger cement. Vacuum systems aid in dust collection/recovery throughout the process, and liquid ring vacuum pumps are used to convey the fly ash due to their inherently rugged design, capable of withstanding the abrasive and corrosive elements to provide long-lasting performance.

Lime is produced by loading crushed limestone into kilns, exposing them to high temperatures. This breaks the limestone into quicklime and carbon dioxide. The quicklime is cooled and mixed with exact amounts of water in a hydrator, causing an exothermic reaction that produces dry, fine hydrated lime powder. Blowers are again used to fuel the combustion with oxygen, fluidize the silos, and cool the quicklime.

For both processes, the raw material is pneumatically conveyed, preheated, blasted in a kiln that is fed a steady stream of ample oxygen, air-cooled, and mixed to create a quality end product. Both processes rely heavily on extreme heating and quick cooling, both of which are conveniently and safely handled by blowers. Blower technology takes the spotlight, but vacuum and pressure technology are found all around in different facilities, being used in myriad ways to boost efficiency and quality.