Aeration

Aeration is the injection of gas into liquid for the benefits that it provides through interaction (bubbling).

Aeration is performed by using a vacuum pump, compressor, or blower to push gas through a mass of liquid. This gas, typically air, is “bubbled” through the liquid, providing the necessary chemical components for the desired chemical reaction. Aeration tanks for wastewater treatment are aerated to promote the growth of aerobic bacteria that break down waste and purify the water. Aeration is utilized for underground water sourcing as well to oxidize the suspended metals such as iron and manganese. Aerating these metals and causing them to oxidize allows for more efficient separation, yielding purer drinking water. In sugar processing, the juice extracted from sugar cane or sugar beets is aerated. Air is pushed into the liquid, bubbling upwards and adsorbing to some of the contaminants. This initial aeration step makes the next carbonation and filtration steps more efficient, increasing the purity and yield of the sugar extraction and refining process. Carbon dioxide and sulfur dioxide are pushed through the liquid, removing the vast majority of suspended particulate matter and doing most of the clarifying work in the refining process.

View our Products

N904 Series

NES Company Inc. N904 Series is a liquid ring vacuum pump, capable of capacities up to 17,200 CFM and 27.5” HgV. The N904 Series drop-in replacement for the Nash 904 and 905 Series boasts a 20-vane design to provide more capacity, more vacuum, and long-lasting service. The liquid ring vacuum pump with properly selected metallurgy is able to tolerate the processing of any gas that it is required to encounter. Particularly for sugar processing, carbon and sulfur process material is capable of conversion into carbonic and sulfuric acid, which can severely damage any pump. With the seal liquid acting as a buffer between the process and the material of construction, and with a superior corrosion-resistant material such as stainless steel, the liquid ring vacuum pump is able to provide long-lasting service in harsh, wet, and dirty conditions. This vacuum pump provides near isothermal processing, tolerance to liquid carryover and small amounts of solids and slurries due to its dual lobe design. Although constant service fluid supply requirements cause operational costs and system design complexity to increase, the liquid ring vacuum pump is favored because with scarce but proper maintenance, these pumps have the potential to last decades.

NL Series

NES Company Inc. NL Series is a liquid ring vacuum pump, capable of capacities up to 15,100 CFM and 26.5” HgV. The NL Series drop-in replacement for the Nash CL Series boasts a 16-vane design, making it one of the more durable options for longer lasting service under harsh conditions. This vacuum pump is capable of reaching high capacities at a rough vacuum level that is applicable towards a versatile range of industries. The liquid ring vacuum pump with properly selected metallurgy is able to tolerate the processing of any gas that it is required to encounter. Particularly for sugar processing, carbon and sulfur process material is capable of conversion into carbonic and sulfuric acid, which can severely damage any pump. With the seal liquid acting as a buffer between the process and the material of construction, and with a superior corrosion-resistant material such as stainless steel, the liquid ring vacuum pump is able to provide long-lasting service in harsh, wet, and dirty conditions. This vacuum pump provides near isothermal processing, tolerance to liquid carryover and small amounts of solids and slurries due to its dual lobe design. Although constant service fluid supply requirements cause operational costs and system design complexity to increase, the liquid ring vacuum pump is favored because with scarce but proper maintenance, these pumps have the potential to last decades.

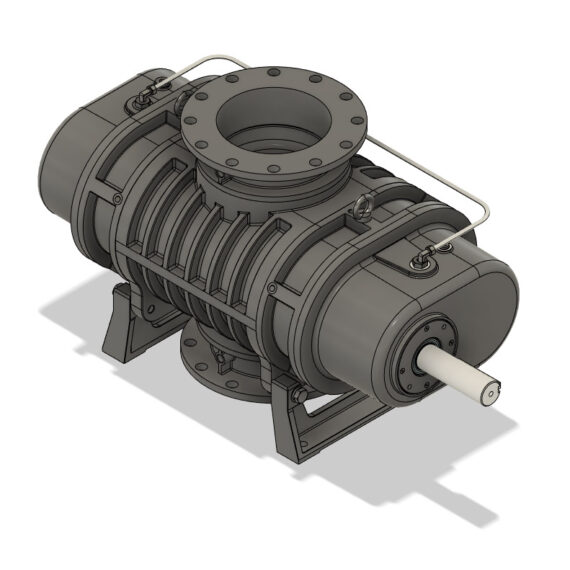

NRB Series

The NRB Series Roots-type blowers are capable of generating 9280 CFM, 14” HgV in vacuum, and 15 PSIG in pressure. Known for reliability and durability, the Roots-type rotary lobe blowers are energy-efficient, low-maintenance, and self-priming. The NRB Series is a functional replacement of MD Kinney PD blowers and boasts a five-point bearing design, double oil tank, synchronous gears, and an optional gas-tight design in case of process gas contamination constraints. Blowers have been used with silencers as an alternative to traditional aerators for industries such as aquaculture and liming for years; they are favored as sturdy and efficient equipment with a higher initial investment cost contrasted by a low operational cost.