Vacuum Blending

The process by which non-gaseous material is often cut and mixed in order to create a uniform consistency in a given product.

Vacuum blending is a process used to create uniform mixtures while minimizing the aerating effect. The blending occurs in a vacuum chamber. Raw ingredients are added, and the blender’s blades or mixing arms are used to agitate the ingredients, drawing out even more air.

Vacuum blending reduces the number of airborne or dissolved oxidative molecules present in the blending process, preserving the shelf life of organic products such as smoothies and sauces. The effect and benefit are extended to the removal of airborne microorganisms that would otherwise proliferate once incorporated into the mixture. The lack of aeration in the blending process allows for a more uniform consistency and texture. Cosmetics and pharmaceuticals benefit greatly from vacuum blending, as the consistency and decrease in oxidative agents creates the opportunity to create creams and lotions with smoother texture and uniform consistency, affecting the packaging process and usage of the product.

View our Products

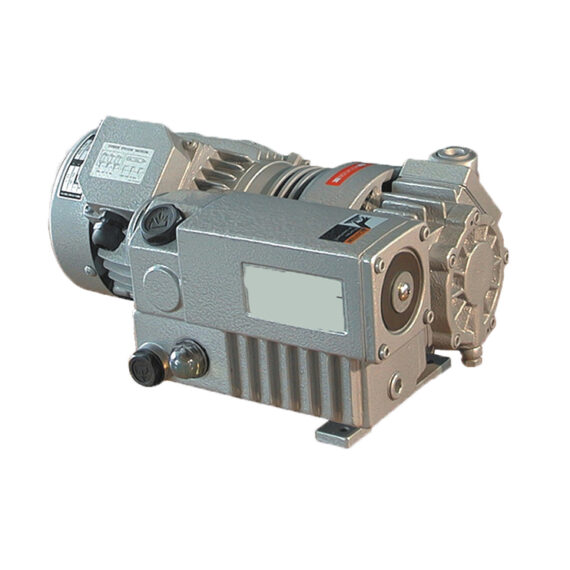

NRV Series

An oil-sealed rotary vane vacuum pump is often used for vacuum pressure swing adsorption applications because it is inexpensive, efficient, and long-lasting. The rotary vane is cheaper in both installation and operation over time compared to dry screw, liquid ring, and dry claw vacuum pumps. This is due to its compact size and simple design with one moving part. This translates to easier installation, simpler maintenance, and faster repairs. The circular design of the rotary vane allows for continuous suction with minimal disturbances in the mass transfer rate. The oil seal acts as a lubricant between the vane-to-chamber contact, a seal between the vane and chamber, and a barrier between mildly oxidative or corrosive process gasses and the metal in the pump. These accessories, such as gas ballast kits and inlet filtration kits, make for smoother rotary vane operation for a longer service life. Accessory kits are entirely optional, meaning that you can pick and choose some, all, or none depending on your industry process.

NTRV Series

The NTRV Series is capable of up to 64 CFM and 1.33×10^(-3) mbar. Two-stage oil-circulated rotary vane vacuum pumps come at a bit higher of a price point than single stage. However, it is still less expensive than many pumps in the market with the same reliability, compact frame, low noise, and versatility. The trade-off for the increased price and design complexity is that these pumps are widely applicable for even deeper vacuum. The NTRV Series vacuum pumps are covered by a one-year warranty against manufacturing defects and are offered with various accessories such as filters and repair kits.

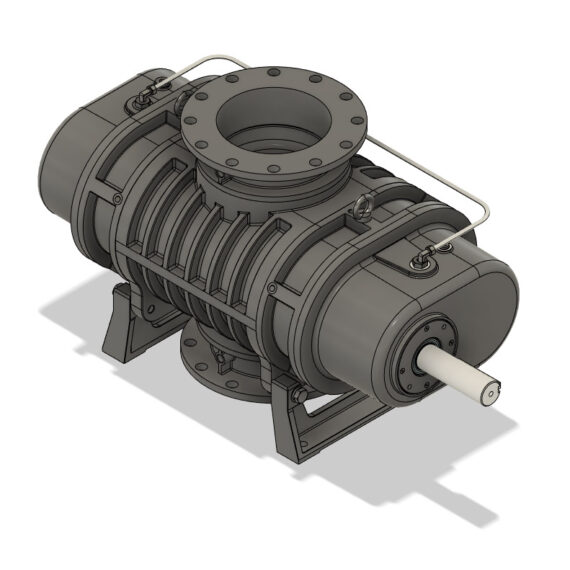

NRB Series

The NRB Series is capable of up to 9280 CFM, 15”Hg in vacuum, and 15 psig in pressure. Roots blowers are incredibly reliable and energy-efficient; they are often used as a standalone unit, or as part of an engineered system. Roots-type blowers are driven by gears that are lubricated separately from the inner casing, so there is no process contamination. NES Company Inc. provides a one-year warranty against manufacturing defects.

NCC Series

Occasionally for beverage, dairy, chemical industry, powder is sucked into a tank full of circulated liquid via vacuum. The dispersed powder is homogenized through blending and mixing without aerating the mixture. This liquid will harm dry-running pumps and degrade the quality of the oil in an oil-circulated pump. Both of these will lead to further costs, whether through constant repair or constant maintenance. The liquid ring vacuum pump requires a constant supply of liquid to create the liquid ring that seals its chamber and generates vacuum, but any stray process liquid will simply pass through the pump without damage to the pump nor to its performance. The NCC Series vacuum pumps are capable of up to 350 CFM and 28”Hg in vacuum. These pumps are built with multiple drain ports to ensure proper operation, maintenance, and storage, as well as an anti-cavitation port to protect the pump from potential damage. These pumps boast a diminutive footprint for space-saving considerations and are available in close-coupled and lantern-frame configurations. NES Company Inc. provides a two-year warranty against manufacturing defects for the NCC Series liquid ring vacuum pumps.