Vacuum Pump Applications in the Food and Poultry Industries

Vacuum technology plays a pivotal role in ensuring the optimal filling of bottles, minimizing air entrapment, and enhancing the overall quality of the processed food products.

Deaeration

Deaeration, achieved through specialized vacuum systems, further refines the quality of the food products by removing undesirable gasses that can compromise freshness and taste. These advanced vacuum applications found in bottle filling and deaeration not only streamline poultry processing operations but also contribute to maintaining the highest standards of food quality and safety. Incorporating these techniques reflects a commitment to excellence in food processing, meeting industry standards and satisfying consumer expectations.

Poultry Evisceration

Evisceration is a process in which innards and blood are removed from livestock in preparation for processing as a food product. This is a very gruesome and filthy process, not to mention a slow one. To mass produce meat, the evisceration process needed to be quicker. Thus, as the age of automation settled in, vacuum eviscerators were invented and are now utilized widely due to the cleanliness and fast timing in which the evisceration process is performed. Operators grab de-feathered and beheaded chicken carcasses off of a conveying hanger. They use a handheld suction pipe, grab a chicken, and the pipe is inserted into the hole previously cut into the bottom of the chicken. The suction is used to pull the internal organs and extra feathers off of the chicken before re-hanging the carcass.

Freeze Drying (lyophilization)

One of the oldest methods of food preservation is drying. Moisture is necessary for bacterial growth, so extracting all of the water from the food discourages bacterial deterioration of food supplies. However, air drying the food does not extract all of the moisture. In certain situations, the food must last for even more extended periods. This can be a marketable quality, and it is also attractive for military applications. Thus, freeze-drying was developed. Freeze drying is the process of freezing a food sample and drawing the water out of the food in subatmospheric conditions via sublimation. First, the sample is frozen at the temperature of at least its melting point. If any water is not frozen, it will evaporate and leave traces of water in the sample. The sample is quickly frozen to prevent large ice crystals from forming and damaging the integrity of the sample. The vacuum pump and drier are simultaneously switched on. The atmospheric pressure in the freeze dryer is usually around 0.5 hPa, or roughly 0.01” Hg, a near perfect vacuum to ensure that all of the water is sublimated. This can take several days. After this, a secondary drying stage is performed. The first sublimates the ice crystals, and the secondary stage is heated even more intensely to ensure complete sublimation on a molecular level.

Another way of preserving food is by simply setting it in vacuum. Removing all airborne bacteria and mold prevents enzymatic breakdown while removing all oxygen prevents certain organic compounds from oxidizing and rotting. This is the concept that produced reduced oxygen packaging (ROP), or vacuum-seal packaging as it is commonly known. Food is put into a plastic bag. This plastic can be polyethylene, polyester, polypropylene, and many other hydrocarbon polymers. These polymers are lightweight, airtight, flexible, and durable for its intended use. The bag is put into a machine that uses vacuum to suck out all of the air in the bag, and heat-seals the bag to permanently induce vacuum until it is reopened.

Extraction of Edible Oils

The chemical method of stripping involves using specific gasses to “strip” molecules out of liquids either countercurrent or along the same current as liquid falls from the top of the stripping chamber to the bottom. This method is used to strip cooking oil of water, unpleasant smells from aldehydes, ketones, alcohols, and thermolabile pigments (colors that deteriorate with heat). The stripping chamber is set to 21-28” Hg of vacuum pressure. In many cases, superheated steam is the stripping agent. This vacuum pressure reduces the boiling point of water considerably and empties the chamber of air, allowing the steam full coverage of the oil that is being poured in and less heat energy required to evaporate. The steam evaporates the water in the oil and strips the various compounds that are deemed undesirable.

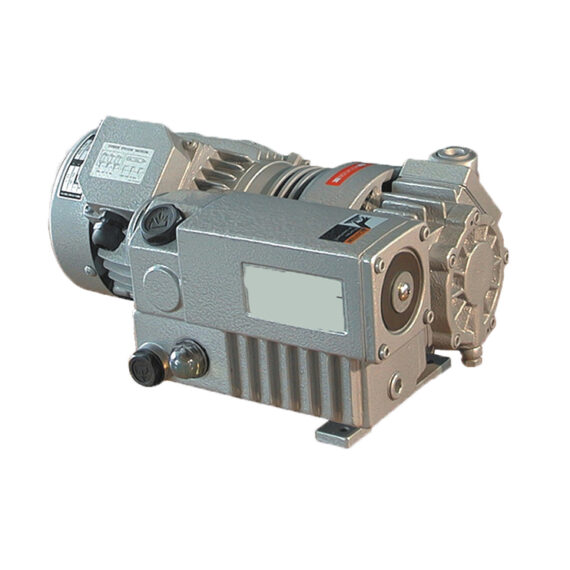

Applications of NES Vacuum Pumps

The liquid ring vacuum pump is preferred for vacuum pump applications in the food industry. Evisceration is an extremely dirty and wet process that involves the suction of blood, small organ pieces, coagulating blood sludge, and stray feathers. The liquid ring pump is able to pass all of these straight through it without any hindrance in suction force. The suction can be routed to all of the operators with considerable force in each handheld unit because even with just a single stage liquid ring vacuum pump, 26” Hg of vacuum pressure can be created, and high levels of CFM can be achieved if requested during the planning phases of pump system construction. The pump can be built corrosion-resistant against all of the acids within the blood, and the pump is always built robustly to withstand the abrasive solid material. The liquid ring pump is widely used today for this application.

Vacuum packaging often involves moisture-rich foods that require preservation. The liquid ring vacuum pump is able to process this moisture without issue and boasts a long service life for constant operation throughout years with bare minimum maintenance.

Freeze drying can be done using a liquid ring vacuum pump. The moisture that is constantly being suctioned out of the freeze dryer will eventually damage vacuum pumps if dry-running pumps are used because of their sensitivity to moisture. This application requires a wet-running, constant suction, long-lasting pump. The liquid ring vacuum pump is a wet-running pump that increases in efficiency when intaking condensable vapors. A dual stage liquid ring vacuum pump can create an environment of 28” Hg on its own and can reach higher with a booster or another pump. The pump boasts a long service life with minimal maintenance and easy repair.

The liquid ring vacuum pump is good for industrial application of vacuum packaging. The pump can be much stronger than it needs to be for one singular vacuum – packaging station, so it can be routed to many separate vacuum packaging machines. It provides constant suction so that it evacuates air without giving any opportunity for air to seep in and properly sucks moisture out without any damage to the pump.

Vacuum stripping is perfect for the liquid ring vacuum pump. Vacuum stripping is usually a process where superheated steam is sucked into and up a chamber where liquid is poured downward. The steam adheres to and removes specific undesirable compounds within the liquid, as well as removing the moisture. The material passing through the pump is hot, condensable vapor moving at high speeds because of the vacuum conditions and the heat energy it withholds. All of the steam condenses in the liquid ring vacuum pump. This condensation within the chambers of the pump creates a vacuum space where even more steam enters. The continual condensation of the steam results only in more intake and condensation of steam, which boosts the mass flow rate exponentially. The pump boasts a decently long lifespan already, but building a corrosion-resistant pump will lengthen the pump’s lifespan even more as it is exposed to hot water molecules condensing and causing pitting in the impeller. If repair needs to be done, it is simple because only so many parts need repair. The liquid ring vacuum pump can pull deep vacuum pressure, leaving almost empty space for the steam to rush in and encompass the oil entirely, allowing for the most efficient stripping process.