The NES Perspective: Plastics, Rubbers, and Composites

Plastics, rubbers, and composites are shaped by precise chemical reactions and forming methods – all powered by vacuum and pressure systems. From monomer to molded product, vacuum and pressure technology make it possible.

Plastics, rubbers, and composites are a few of the most versatile materials in modern manufacturing, foundational to industries from packaging to aerospace. Each material varies vastly in flexibility, durability, and form via an even larger array of chemical reactions available to manufacturers to pinpoint the desired physical and chemical characteristics for each industry they serve. From raw polymer synthesis to final forming, vacuum and pressure systems support critical operations to ensure purity, performance, and efficiency.

The ground level of most plastics and synthetic rubbers is polymerization, by which monomers that have been distilled and cracked from crude oil undergo addition/condensation reactions. In addition reactions like the reaction of ethylene into polyethylene, a free radical initiates the reaction and an ethylene molecule breaks its pi bond to join with the radical and form a sigma bond and another free radical. An ethylene molecule approaches this free radical, and the chain continues to form long polymer bonds.

View our Products

In condensations reactions like for PET (polyethylene terephthalate) synthesis, two molecules (terephthalic acid and ethylene glycol) react and form two products: a polymer chain of PET and water (the condensation). Both of these kinds of reactions require vacuum to prevent oxidation and increase yield, as well as an inert gas blanket to the same effect. Post-polymer formation, these plastics and rubbers are formed into pellets for bulk handling and ease of metering.

Occasionally the plastics or rubbers need to be compounded, or mixed with other ingredients. This included other plastics or rubbers, plasticizers, stabilizers, fillers, and more to enhance properties like strength, optics, and flexibility. Certain fillers or pigments cause gasses to dissolve or become trapped within the mixture, so the line is continuously degassed. Removing these gasses is important to maintain the chemical structure and exact physical properties that are desired of the end product.

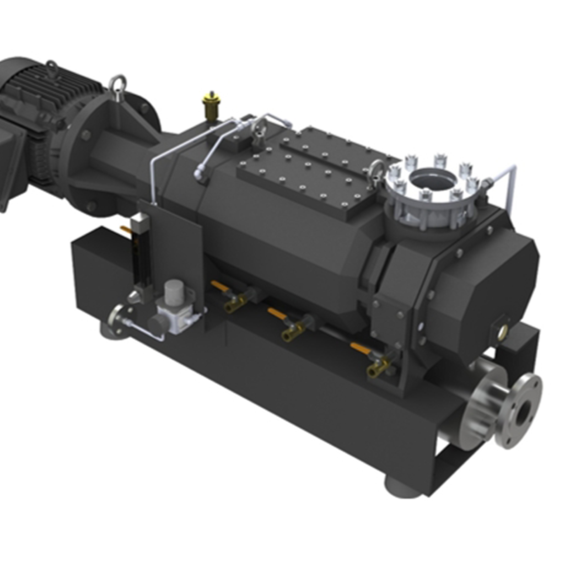

The pellets are easily handled and transported across large distances using pneumatic conveying. Typically, dense-phase conveying is employed to protect the quality of the pellets and reduce the number of fines generated from the conveying process. This involves the use of compressors to allow pellets to travel larger distances or with higher throughput. In this manner, a consistent flow of pellets can be metered via rotary airlock valve and conveyed to and from silos.

There are two kinds of polymerization: chain-growth polymerization (addition reaction) and step-growth polymerization (condensation reaction). In the addition reaction, only one type of monomer is used. The monomers are combined and form double or triple carbon bonds. This method does not involve any loss of molecules. In the condensation reaction, atoms like nitrogen, oxygen, and hydrogen are combined with different kinds of monomers. These different things combine and leave a condensate. This reaction does involve the loss of molecules, and the condensate is usually water.

The result of the polymerization of propylene and ethylene is plastic, of which numerous kinds have unique qualities. These hydrocarbons are inert and very hard to degrade, so they are the preferred choices for plastic, synthetic rubber and many composites. After polymerization, the plastic is ready to be formed.

Once the polymer is formed, it is available for use. Of the methods of forming plastic, there is 3D printing, CNC machining, polymer casting, rotational molding, vacuum forming/thermoforming, injection molding, extrusion, and blow molding. The decision of which to use depends on lead time, budget, design complexity, and production volume.

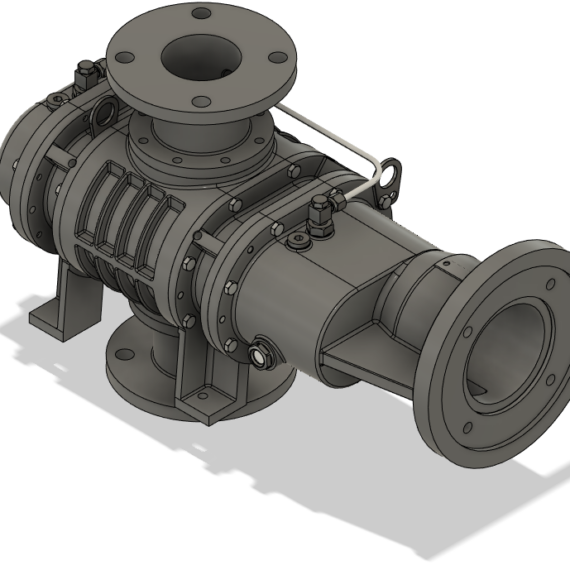

Mass manufacturing simple forms like trays and containers has been simplified and enhanced by the development of vacuum thermoforming. The plastic is formed into continuous sheets which are fed to a heater. This heater softens the sheet up to a certain length and lowers the heated plastic onto a carefully designed mold. As the sheet is brough all the way down onto the mold, a vacuum pump evacuates the space in between the mold and the sheet. This brings the sheet to hold tightly against the mold such that the plastic cools and hardens into a complex shape in mere minutes. Without the use of vacuum the completed forms would be blobs, mere shadows of their intended image.

As can be seen, vacuum and pressure are consistently and reliably used from the first monomer to the last end product. Synthesis reactions and gentle transport relies on such systems to boost efficiency, if not to be realized in the first place. NES Company Inc. is proud to support this ever-growing industry with high-performance vacuum pumps, blowers, compressors, and rotary airlock valves that deliver efficiency, consistency, and long-lasting service to rise above and beyond the industry standard.