Rotary Vane Pumps for the Nuclear Industry

Nuclear science has expanded our knowledge of how the world works, and how we can use it to our advantage. This has led to advancements in technology relating to environmentally friendly energy, bolstered military defense, modern medicine, biodegradable materials, complex semiconductor microprocessors, and even high-sensitivity residential smoke detectors.

Nuclear power is generated by heating water using the energy generated from nuclear reactions. These reactions can either be fission or fusion, splitting or forming radioisotopes in a way that releases energy. The energy promptly heats the water, causing it to change phase and become steam that is led to the turbine to spin the rotor and generate electricity through the electromagnetic properties of the rotor-stator design of the turbine. This is done through a pressure vessel. Radioactive elements such as uranium and plutonium are mined, beneficiated, and processed into small ceramic pellets. These pellets are loaded into metallic rods, and these fuel rods are packed into fuel assemblies with control rods inserted into them to control the rate of reaction.The assembly is submerged in a pressure vessel filled with water, and the power generation begins. The controlled rate of reaction releases a calculated amount of energy from the assembly to the water, rapidly heating it. From here, two methods are commonly used.

In a pressure-water reactor (PWR), the water in the pressure vessel is constantly recirculated. The water is pressurized so that it stays as extremely hot water. This water is sent through a coiled pipe that is in the center of a steam generation tank. The steam generation tank acts as a heat exchanger, as cooling water is poured in this tank and interacts with the irradiated water to make steam. The pressurized water cools and continues through the piping straight back to the pressure vessel with the fuel assembly, never coming into direct contact with the cooling water or the turbine. The cooling water turned steam spins the turbine, falls into the condenser, condenses into liquid phase, and either undergoes treatment or recirculation.

In a boiling water reactor (BWR), the irradiated water is freely allowed to shift into steam and directly rotate the turbine. The assembly heats the water, which turns to steam and rotates the turbine. The water enters the condenser and recirculates with the cooler water. This heats the cool water up for higher thermal efficiency

Nuclear research typically involves the creation and observation of radioisotopes in a controlled environment. By accelerating and colliding particles in a cyclotron or particle accelerator like the Large Hadron Collider, researchers are able to study the behavior of certain radioisotopes and formulate conclusions on the general behavior of naturally occurring particles of both stable and unstable constitution.

Applications of NES Vacuum Pumps

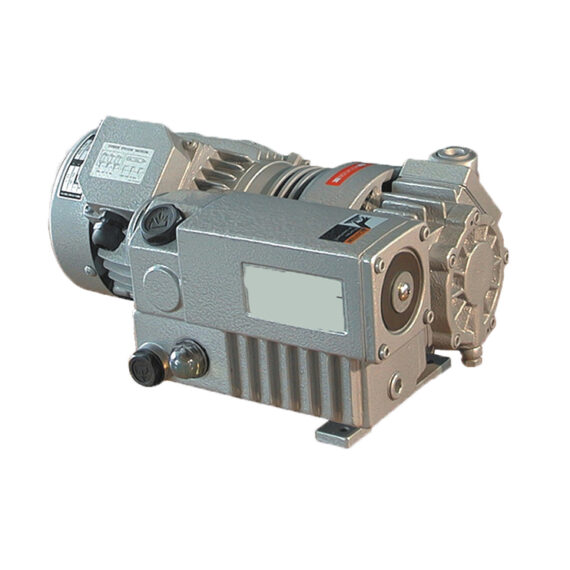

Oil-circulated rotary vane pumps are used in both power generation and research applications.

In a nuclear power plant, the pressure vessel casing has two layers of metal with an interlayer of vacuum in between. This vacuum acts as both isolation and containment for radioisotopes and the energy that they emit. Using a hepa filtration system, radioactive gas can be effectively contained and its resultant energy utilized.

In research, oil-circulated rotary vane vacuum pumps are used as backing pumps for higher-level vacuum producing vacuum pumps, like turbopumps and ion diffusion pumps, that are typically used to create the artificial negative pressure required. The cyclotron and particle accelerators need less molecules inside of the accelerator so that the accelerated particle is able to reach the high speed required for fusion and fission. These higher vacuum pumps require meticulous and painstakingly thorough maintenance and care because of the structural drawbacks that come with producing deeper levels of vacuum. To use these pumps in a way that requires less stress and loading on such expensive and complex equipment, the vacuum level is brought up to rough or medium levels of vacuum by an oil-circulated rotary vane vacuum pump. This makes for less load that the other pump needs to bear to raise the vacuum level from atmospheric pressure to extreme negative pressures approaching a complete vacuum state.

Advantages of NES Vacuum Pumps

The oil-flooded rotary vane vacuum pump is a commonly used backing vacuum pump for both power generation and particle accelerator evacuation.

The benefit of using this pump as a backing pump is that it is a sturdy pump that is able to provide an undisturbed mass transfer rate at a wide range of vacuum levels. The oil circulation lubricates and seals the space between the vanes and the chamber, allowing for higher vacuum levels and longer lasting service with less wear on the vanes over time. The oil and filtration systems need maintenance, but the parts are few and simple, resulting in easy maintenance and simple repair. In addition to all of this, rotary vane vacuum pumps are of the most inexpensive vacuum pumps in the modern market.

NES Company Inc. proudly presents the NRV Series oil-flooded rotary vane vacuum pumps. These robust pumps are the optimal choice for nuclear power pressure vessel interlayer evacuation systems and particle accelerator evacuation systems backing pumps.