Research Industry Rotary Vane Vacuum Pumps & Compressors

Through various analytical and transformational methods in laboratory research settings, discoveries are made which newly shape the foundations of society and technology, from your food to your phone. In most of these precise instruments and detailed experiments, vacuum is used to provide the cleanest, clearest data.

Mass spectrometry is an analytical method used to identify molecules based on the measurement of the molecular weight of their elemental constituents. A mass spectrometer does this by separating ionized particles depending on their mass to charge ratio and relative abundance. A sample is injected into an evacuated tube. Upon entry, the sample is ionized by an electron beam supplied by an ion source. These ionized particles are accelerated by a magnetic field, which separates the ions by their charge/mass ratio and sends them towards a detector. The detector is able to quantify the charge and mass of the particles, as well as how many of the specific particles there are. This is useful in forensic research, when there is a small biological sample that needs to be studied. This is also very useful in cancer screening, biofuel research, and other research that is done currently on the properties and composition of certain biological compounds.

Electron microscopy is an analytical technique by which microscopic samples are imaged with enormous magnification through the use of an electron beam. An electron source, or “gun”, propels electrons. Inside of the gun, a small metal plate is connected to low voltage and heated. The electrons are free to move through the metal plate, and as it is heated, the electrons gain energy that is exhibited as kinetic energy. The plate is heated continuously, and electrons begin to gain enough kinetic energy to escape the metal surface. These electrons are shot straight to the sample through magnetic lenses and coils to the sample. Back-scattered electrons and X-rays are the byproducts of the electrons traveling and hitting the sample. These electrons and X-rays are picked up by the scan generator, which forms an image out of said byproducts. Because the electrons are so small, they are able to produce incredibly detailed images from microscopic samples as so many are able to hit and bounce off of the sample, even at a scale that is practically invisible to the naked eye.

Rotary evaporators, or rotovaps, are apparatus which use the influence of pressure on boiling point to selectively evaporate liquids and separate them from the rest of a mixture. This equipment is mostly used to separate a solvent from a solid solute. A solution is placed in a flask that is partially submerged in a circulated bath of ice water. A vacuum pump lowers the pressure inside the flask, causing the boiling point of the solution to lower. By controlling the temperature and pressure of the solution, the solvent can be extracted without raising the temperature to a degree at which some solutes can degrade or combust. This ensures a higher quality yield of solute and a safer working environment.

Centrifugal vacuum concentration is a subtractive process by which solutions increase in concentration through the manipulation of pressure to speed up the evaporation process of solvents, similar to the physical principles of the rotary evaporator. The setup is different in that centrifugal force and heat are used to accelerate the heating process while preventing solvent bumping, which occurs when superheated solvent begins to bubble erratically, resulting in loss of solution. Bumping is especially prevalent in concentration of small samples of solution, and centrifugal vacuum concentration is used to turn small samples into wet or dry pellets.

Vacuum ovens provide the ability to dry samples in a controlled environment with a specific pressure level. This means that there is a level of control over atmospheric oxygen, contaminants, evaporation rate, and margin of error in chemical processing. By using a vacuum oven instead of a conventional oven, the drying time decreases, final moisture content decreases, and quality increases as a result.

A fume hood is part of a laboratory ventilation system that allows for proper handling, experimentation, or reaction of potentially toxic or otherwise harmful fumes during any chemical process, experimental, manufacturing, research, or otherwise. The fume hood itself is a piece of equipment that features a large overhead vent. Samples that emit potentially hazardous vapors are placed under the hood, where suction draws the fumes into the ventilation system of the fume hood. There are many different fume hood systems, with some recirculating the air into the workspace after filtration and others being connected to the building’s HVAC system. For particularly heavy-duty fume hoods, a vacuum pump is used to provide stronger suction for samples that are especially prolific in production of toxic fumes.

Vacuum filtration is a subtractive process by which a mixture is separated by its solid and liquid components via suction through a filter with microscopic pores. A solution of liquid-solid suspension is poured into a funnel like a Buchner funnel. A filter is installed at the bottom of the filter that has microscopic pores; these filter pore sizes vary depending on intended use. A vacuum pump is connected to a safety trap, which is then connected to the receiver flask that holds the funnel above it. The vacuum creates a negative pressure which draws the contents of the funnel through the filter at a quicker rate. This cuts operation time, which cuts operation cost.

Applications of NES Vacuum Pumps

Mass spectrometers and electron microscopes are typically held in vacuum by ultra-high vacuum level pumps, such as a turbomolecular pump or a diffusion pump. These pumps are paired with backing pumps such as oil-sealed rotary vane vacuum pumps so that the expensive and complex ultrahigh vacuum pumps can be used for less time to raise the vacuum from a higher starting point for less loading. Mass spectrometers need to be evacuated so that the ions can travel at the intended velocities without interruption. Electron microscopes need to be evacuated so that the traveling electrons are undisturbed in path and velocity. If these are not evacuated, ambient air molecules will prevent any high-speed travel as the ions or electrons bump into the air molecules and lose kinetic energy by means of collision.

Rotary evaporators, centrifugal vacuum concentrators, and vacuum ovens all operate on the decreasing of pressure to lower the boiling point of liquid samples. Since the boiling point of liquid samples is dependent on the vapor pressure and the pressure of its surroundings, lowering the pressure of the chamber inside the vacuum oven allows for the vapor pressure to easily reach that of the surroundings. Without the vacuum pump, these sets of equipment are unable to perform their basic function. For these applications, the oil-sealed rotary vane vacuum pump has long been a standard choice.

A heavy-duty fume hood makes use of an oil-sealed rotary vane vacuum pump because the system cannot draw the hazardous fumes out of the workspace at the correct rate using only an exhaust fan. Typically, the exhaust fan creates small levels of vacuum that are able to draw trace amounts of fumes, but with samples such as toxic volatile compounds, higher levels of suction need to be achieved for a completely safe working environment.

Vacuum filtration makes use of the oil-sealed rotary vane to create enough vacuum in the receiver flask to draw the substances from the funnel through the filter.

Advantages of NES Vacuum Pumps

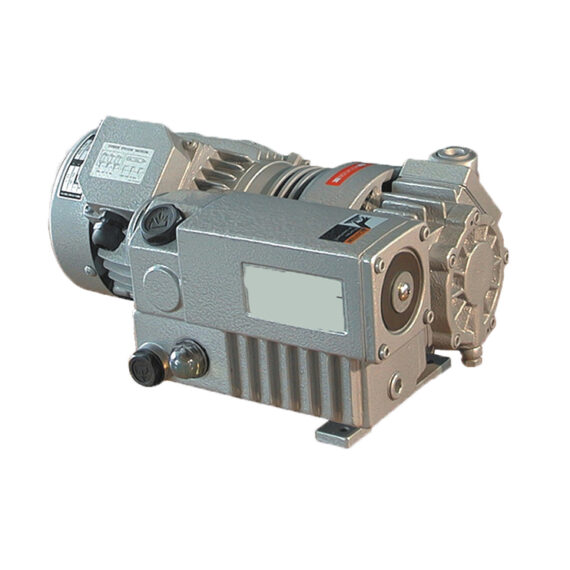

NES Company is proud to offer the new line of oil-flooded rotary vane vacuum pumps, our NRV series. The oil seal in the NRV models allows for deeper vacuum, which benefits the turbomolecular or diffusion pumps when applied to mass spectrometry or electron microscopy. The higher the rotary vane pump is able to bring the magnitude of negative pressure, the easier it is for the primary pumps to raise it to the proper level of ultra high vacuum. The higher vacuum level that oil-circulated rotary vane vacuum pumps are able to provide is also beneficial for rotovaps, centrifugal vacuum concentration setups, and vacuum ovens. Using proper inlet filtration and metallurgy for chemical resistance and corrosion resistance, the NRV model rotary vane vacuum pumps are able to aid in evaporating water and solvents as a primary pump, creating an atmospheric pressure of up to 0.5 mbar. This vacuum level is more than sufficient enough for both fume hood and vacuum filtration applications. The rotary vane vacuum pump is inexpensive compared to other pumps, and its simple design allows for easy maintenance and quick repairs, which are both important features in a backing pump that needs to efficiently operate often for long periods of time.