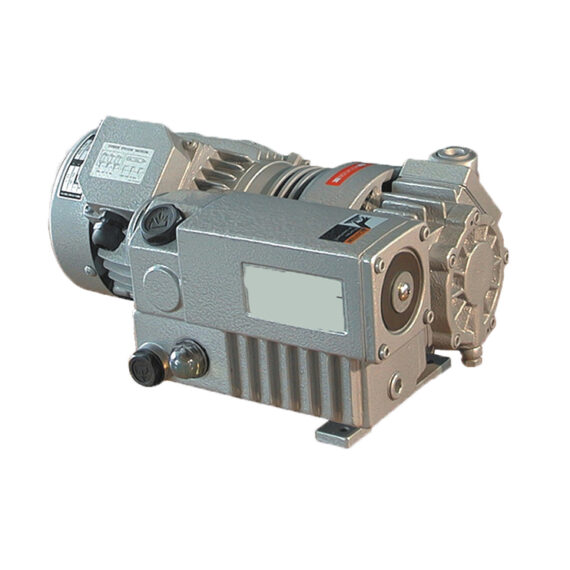

Vacuum Conveying Rotary Vane Vacuum Pumps & Compressors

As mass production grew in worldwide application, conveying products became essential for industry operations. Now, there are no factories that do not have some form of conveying. Soda cans are cut and filled on belts, paper speeds through drying and cutting through rollers; efficiency cannot be achieved without conveying. Belts and rollers do their job well, but when it comes to pick-and-place operations, no technique works as well as vacuum conveying.

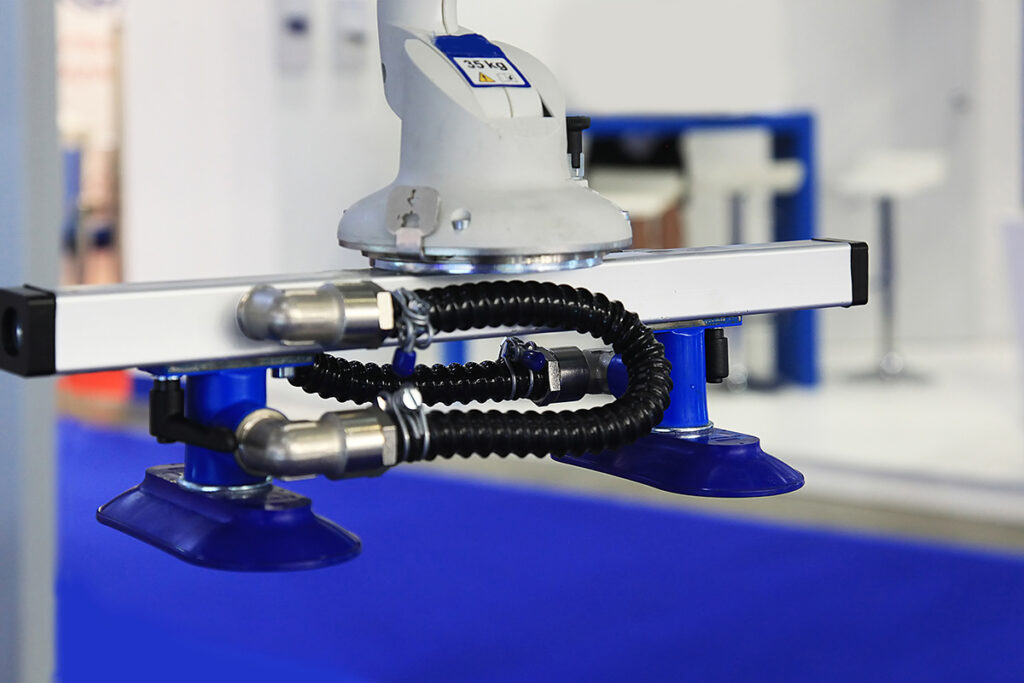

Vacuum conveying is the method of moving products further down the production line through the means of using suction to relocate products. Vacuum conveying takes many forms: sometimes suction arms are used to lift products and place them on different lines, sometimes suction pads are used to package products, and in especially in the paper industry, suction rolls guide the direction and increase the acceleration at which thin products are processed. The essence of vacuum conveying is this: if a product needs to be removed from its belt to be moved in a different direction or onto a different part of the process, vacuum conveying picks it up and puts it down where it needs to be.

Using robotic arms does a similar job, but cannot be done with a large amount of fragile products. Extra expense and care must be taken so that the arm is properly calibrated and equipped with the ability to handle such a task. Magnetic pick-and-place operations do a similar job with similar quality, but as one might assume from its name, they can only be applied to magnetic products.

Besides vacuum-mechanical operations, there are methods of vacuum conveying that transport powders and bulk solids from a silo across large distances of piping. This kind of conveying is also implemented in fly ash recovery in power plant processes. By using vacuum instead of a positive pressure method that pushes the material through the pipe, the process can be done with minimal amounts of dust in the piping and the pump as the negative pressure draws it out before beginning the conveying process. Dry-running pumps are better suited for this application.

Applications of NES Vacuum Pumps

In pick-and-place and vacuum conveying applications, an oil-flooded rotary vane vacuum pump is commonly used. The transferring of ceramics and glasses such as vases, wine bottles, mugs, and window panes requires delicate and firm handling, unlikely a job for a mechanical gripping arm. The products are nonmagnetic, so magnetic arms and pads are unable to efficiently perform the conveying maneuver. Meanwhile, the use of vacuum pads and vacuum arms for the transfer of wine bottles has already been continuously popularized and used historically in tandem with a rotary vane vacuum pump.

Oil-flooded rotary vane pumps are not suitable for vacuum conveying, but are optimal for vacuum-mechanical operations such as suction rollers, vacuum pads, and vacuum arms.

Advantages of NES Vacuum Pumps

An oil-circulating rotary vane vacuum pump is so widely used because it has numerous desirable qualities that make it an obvious choice. The oil acts as a barrier between any metal-to-metal contact, reducing friction, heat, and potentially corrosive process gasses. The oil holds dust and emulsifies with water, so the oil will need an immediate change so as not to affect the performance of the pump, but the pump will not need replacement or repair. The oil seals the microscopic gaps between the vanes and the chamber, resulting in a higher achievable vacuum level than a dry-running rotary vane vacuum pump.

NES Company Inc. boasts the NRV Series oil-lubricated rotary vane vacuum pump because of its robust design and the availability of spare part kits. The rotary vane is already a relatively simple design with easy maintenance. Repair is not needed very often, but it is very easy to perform when it is needed. The NRV series models are able to create a constant suction that is tailored to the specific ultimate vacuum pressure and power rating needs of any pick-and-place vacuum application in mass manufacturing. Along with the 1 year warranty against manufacturing defects, the NRV series shows its quality in design, lifespan, and service.