Rotary Vane Vacuum Pumps for Vacuum Pressure Swing Adsorption

Vacuum Pressure Swing Adsorption (VPSA) is a technique in which gaseous mixtures are separated into their constituent elements, similar to how distillation isolates and extracts the individual components of a liquid mixture.

Adsorption is the physical phenomenon in which a solid holds gaseous or liquid molecules by way of intermolecular bonds such as hydrogen bonds and Vander Waals interactions. This particular phenomenon is beneficial for extracting individual components of mixtures for applications such as non-degradable substance removal from groundwater sources, proper filtration and operation of gas masks, and removal of compounds that produce undesirable colors or textures in juices and vegetable oils. The phenomenon can be artificially induced by way of various different techniques, one of them being vacuum pressure swing adsorption.

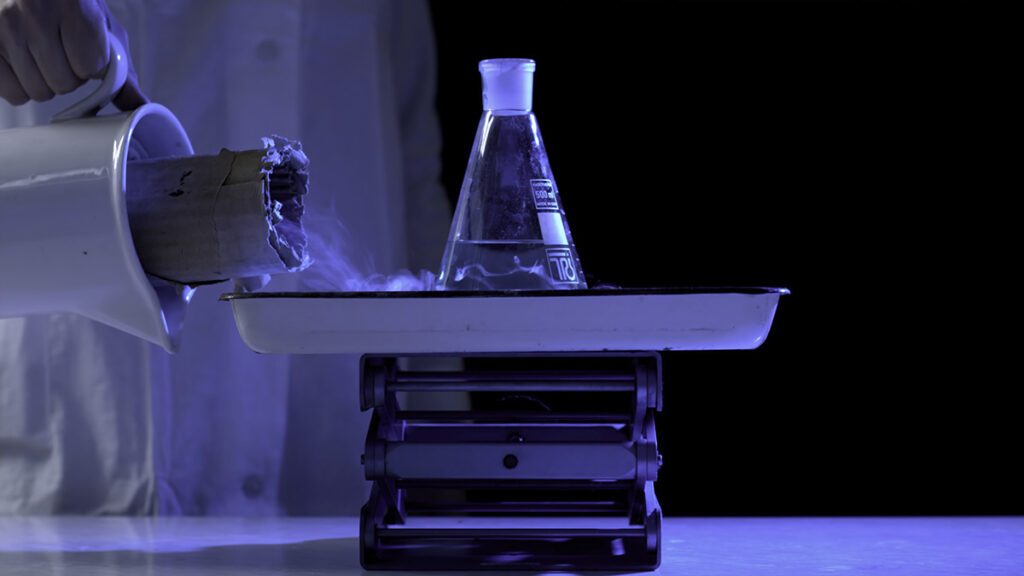

VPSA entails compressed waste air sent through various absorber tanks. These tanks are full of molecular sieves constructed of sorbents such as zeolite. Zeolite is a mineral that is highly porous with differing size pores depending on the molecule that is subject to adsorption. It is often used for nitrogen oxide monitoring and adsorption of volatile compounds such as butadiene, a hazardous irritant gas that is often used to synthesize rubbers and plastics. The molecules of the sieve adhere to the element, whether it be hydrogen, nitrogen, oxygen, water vapor, or carbon dioxide. The intermolecular interactions between the sorbent and adsorbed element are strongest within the pores, where the greatest amount of surface area is able to interact with an individual molecule.

The compressed air is taken in as feedstock through the adsorbent layers, or adsorbent bed, of the absorber tanks. The desired molecule adsorbs to the sorbent, and the rest of the compounds simply pass through. The only adsorbed molecules are the ones that are able to fit in the pores of the sorbent material. The feed gas is compressed, typically through a blower, to increase its pressure so that it may accelerate once the cross-section area of its travel path increases from pipes to the tanks. The velocity of the feed gas increases and it passes through the molecular sieves, getting stripped of specific molecules. The rest of the gas is then drawn out of the tank by a vacuum pump.

Applications of NES Vacuum Pumps

The vacuum pump in a vacuum pressure swing adsorption plant creates suction that allows for continuous processing and adsorption, cutting downtime and raising efficiency in operation costs and daily yield. A common application of VPSA is with oxygen generation. Ambient air is compressed into the plant system, where molecular sieves of Zeolite or lithium collect nitrogen, water vapor, and carbon dioxide. The oxygen passes straight through the absorber tanks, separated from the remaining constituents of the ambient air (argon, helium, methane, etc.) that is suctioned out of the tank by the vacuum pump, transporting it back into the atmosphere. If there were no outlet from the absorber tanks, the remains of the atmospheric air would build up within the tanks, creating back-pressure on the compressor and piping. This creates significant reduction in efficiency, reduction in compression ratio, and possible damage to or failure of the plant system. With simple piping outlets, the back-pressure is reduced but still notable. The process only picks up pace and raises greatly in efficiency when a vacuum pump is included in the system to remove the remains of the waste air.

As a result of VPSA, high purity yields of hydrogen, oxygen, carbon dioxide, and nitrogen gas are able to be produced and distributed for sale across industries. Hydrogen gas is used for energy to produce heat, electricity, and transportation fuel. Oxygen gas is used for raising bacteria culture in wastewater treatment, respiratory aid in medical institutions, glass blowing, ozone generation, and nitrous oxide reduction in fuel burners. Carbon dioxide is used as filling gas for carbonated beverages, cooling of metals and preservation of vaccines as dry ice, and fire extinguishing. Nitrogen gas is used in chemical laboratory sample analysis as well as in production of nitric acid, which is used to make various products including fertilizers, explosives, and dyes. Because of the wide range of applications of each of these gasses, vacuum pressure swing adsorption is an important process that spans across most industries.

Advantages of NES Vacuum Pumps

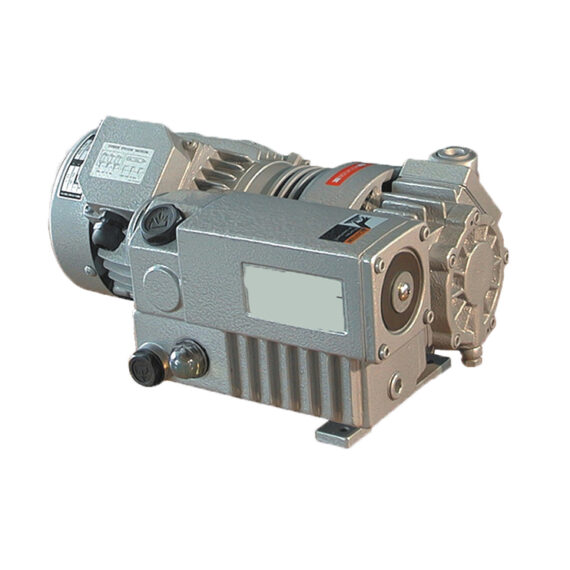

An oil-sealed rotary vane vacuum pump is often used for vacuum pressure swing adsorption applications because it is inexpensive, efficient, and long-lasting. The rotary vane is cheaper in both installation and operation over time compared to dry screw, liquid ring, and dry claw vacuum pumps. This is due to its compact size and simple design with one moving part. This translates to easier installation, simpler maintenance, and faster repairs. The circular design of the rotary vane allows for continuous suction with minimal disturbances in the mass transfer rate. The oil seal acts as a lubricant between the vane-to-chamber contact, a seal between the vane and chamber, and a barrier between mildly oxidative or corrosive process gasses and the metal in the pump.

NES Company Inc. is proud to offer the NRV Series Oil-Flooded Rotary Vane Vacuum Pump with optional accessories and a spare parts kit for a comfortable DIY maintenance and repair experience. These accessories, such as gas ballast kits and inlet filtration kits, make for smoother rotary vane operation for a longer service life. Accessory kits are entirely optional, meaning that you can pick and choose some, all, or none depending on your industry process.