The NES Perspective: Chemical Processing

The chemical industry depends on vacuum and pressure systems as a foundational element of its various processes. From lyophilization to membrane separation, these technologies enhance purity and control at every step.

Applications

- Adsorption

- Blending & Mixing

- Lyophilization & Sublimation

- Membrane Pervaporation

- Refrigeration & Cooling

- Steam Recompression

- Gas Recovery

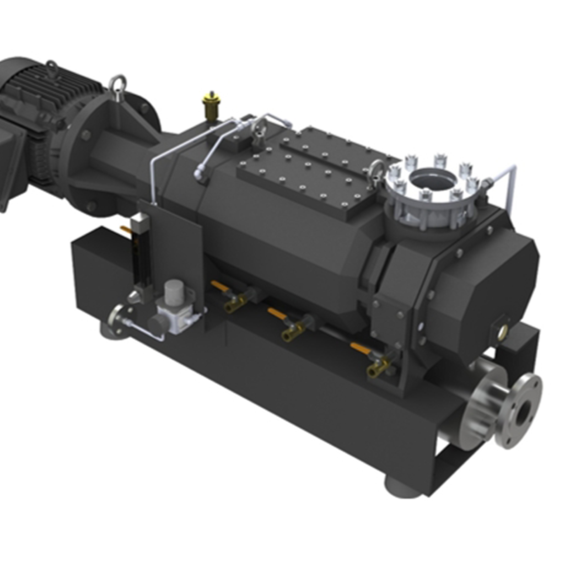

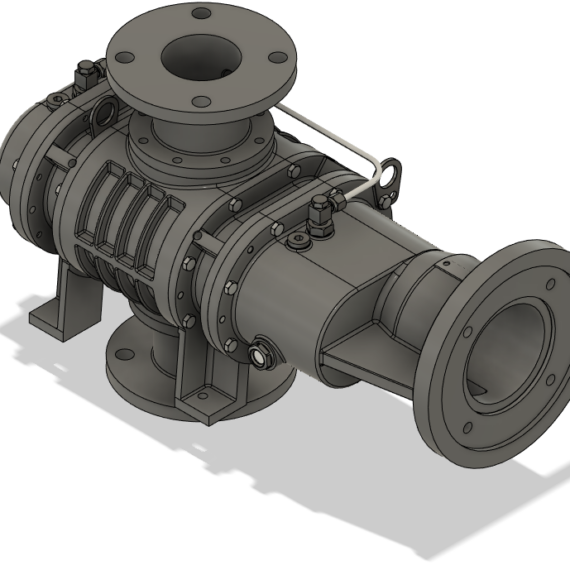

View our Products

The chemical industry relies on tightly controlled physical and thermodynamic processes to synthesize, separate, purify, and transform a wide range of compounds – from base chemicals to advanced polymers and active pharmaceuticals. In nearly every unit of operation, vacuum pumps, compressors, and blowers act on central stage to regulate reaction environments, enhance separation techniques, and reduce energy consumption across all batch and continuous systems.

One of the most advanced separation techniques in the industry is vacuum pressure swing adsorption, VPSA. VPSA is used to isolate gasses like oxygen, nitrogen, and hydrogen from ambient air or process gasses. The system consists of multiple adsorption vessels packed with sieve materials that are able to adsorb the select gasses at a high pressure. When the pressure is lowered (often to negative degrees), the adsorbed gasses release and the bed is regenerated. The utilization of a vacuum system increases output and aids in full adsorption bed regeneration. VPSA systems are cheap and safe to run continuously with alternating beds, and are favored in particular for industry-scale oxygen generation and hydrogen recovery.

Blending and mixing often involves air entrapment and entrainment into viscous liquids, polymers, and emulsions. This air is removed via vacuum systems to degas the product, reducing oxidation and preventing foaming. When volatile solvents are involved, closed-loop systems are used to avoid unnecessary emissions and reduce costs through solvent recovery.

Freeze-drying, or lyophilization, is an important step for products that are heat-sensitive or require long-term stability. The product is frozen and placed under deep vacuum. In such pressure conditions, the solid water and solvent is allowed to sublimate, transitioning right past the liquid phase to vaporize immediately. This process requires a reliable high-vacuum pump, often in tandem with a cold trap or cryogenic condenser. While these high-vacuum pumps are often finicky, the precision in pressure control and hold time is paramount for structure preservation and yield conservation.

Membrane pervaporation is a separation process that removes select compounds from liquid mixtures using a semi-permeable membrane under vacuum. The permeate side of the membrane is maintained under 1-10 mbar(a) using vacuum pumps. This creates a partial pressure gradient across the membrane that draws specific molecules across in vapor form. This makes mixtures, particularly azeotropic mixtures, easer to separate and recover. Vacuum and flow rate consistency are key to avoid membrane fouling and ensure efficient operation.

Refrigeration is used extensively for chilling and liquefaction operations, with vacuum-assisted refrigeration systems used for low-temperature crystallization and cold traps. In cryogenic applications like LNG or compressed gas processing, multi-stage compressors and vacuum-insulated transfer systems keep efficiency and containment at its best while rougher vacuum pumps provide an intermediary evacuation step to preserve the life of a cryogenic pump.

Mechanical vapor recompression draws steam or solvent vapor from an evaporator or distillation unit, compress it, and return it to the system at a higher temperature, creating a kind of closed-loop system. Compressors are extremely important in MVR and in some cases vacuum pumps are used to maintain low pressures at certain points in the system, drawing the recompressed vapor to areas of interest and boosting efficiency.

Solvent recovery stems from the emissions and waste that is generated from the use of solvents in chemical synthesis and refining. Solvents like acetone, methanol, and toluene are evaporated from a mixture and captured. The vapor is drawn using vacuum, condensed in recovery coils, and filtered or distilled before reintroduction into the process or recycle into different processes. The presence of vacuum lowers the boiling points of the solvents, allowing them to evaporate at lower temperatures. This is especially beneficial for flammable or heat-sensitive solvents that may combust or degrade in the presence of excessive temperatures.

Without even mentioning the thousands of reactions that require precise temperature and pressure control, the chemical industry’s dependence on pressure and vacuum control is obvious and foundational. NES Company Inc. provides high-performance vacuum pumps and compressors required for batch and continuous chemical operations, helping producers achieve tighter environmental control, better product consistency, and higher overall process efficiency.