Wastewater and Effluent Treatment Applications for Vacuum Pumps & Compressors

The sheer number and population of factories and cities produce mass amounts of waste that accumulates as nature struggles to maintain equilibrium. Thus, modern society has implemented treatment infrastructure, which uses vacuum systems to effectively clean the septic and dangerous material.

Applications of Vacuum Pumps & Compressors

Cities are designed to channel wastewater through a sewer system. This water is screened for large debris, such as sticks, rags, and litter to prevent unnecessary damage to the pipes; the solids are displaced to a landfill. The remaining wastewater is pumped to a grit chamber to remove sediment.

The heavier sediment sinks to the bottom of the chamber and floating impurities like grease or small plastics are skimmed off. The sludge at the bottoms of the tanks is removed and pumped elsewhere for digestion while the remaining wastewater is pumped away. The water is run through a clarifier, which mixes chemicals like polyelectrolytes and ferrous sulfate into the water. These bond with the remaining fine sediment in the water and cause it to fall to the bottom of the clarifier for extraction. Now, the wastewater is liquid and broken-down organic matter. The speed of the flow is very important here. Too fast, and nothing will be clean. Too slow, and it will affect the process farther down the pipeline.

The next step is the aeration tank, where oxygen is pumped in to promote the growth of microorganisms that aerobically digest the remaining organic material into cell tissue, water, and nitrogen. The remaining waste, and any excess bacteria, is filtered through another sedimentation tank. In anaerobic digestors, the oxygen is pumped out of the tank, encouraging the growth of bacteria such as methanogens, which digest the organic matter and produce methane that is refined and stored to be used as fuel. After digestion, the water is sent to chemical treatment.

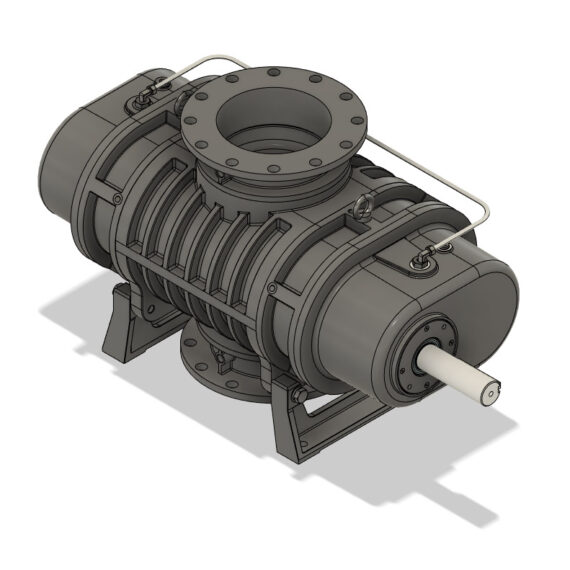

A common form of chemical treatment is chlorination. Chlorine creates hydrochloric acid within the water and bonds with the membranes of waterborne bacteria, acting as an inexpensive sanitizer for the water. The wastewater can also be disinfected using ozone. By pushing oxygen through an ozone generator and compressing the ozone to make it easier to store and access in concentrated amounts, treatment plants have access to large amounts of oxidating agent by which bacteria cell membranes can be destroyed, killing numerous strains of microbial species that are the detriment to the water’s potability. This ozone is often compressed using liquid ring compressors that are able to gently handle and compress the gas to high pressures reaching far beyond one or two atmospheres.

After the treatment, the water is tested for pH, percent of dissolved oxygen per unit volume, ammonia levels, and nitrate levels to match the permitted standard. It is then released into local waterways, like rivers.