The NES Perspective: Vacuum Pumps and Compressors for Cheesemaking

Cheesemaking relies on vacuum and pressure systems for precise dewatering, hygienic vacuum sealing, mold drainage, and temperature-controlled aging. From the first curd formed to the last second of aging, technologies ensure clean, efficient, and scalable dairy production.

- Dewatering/Drying

- Packaging

- Refrigeration/Cooling

View our Products

Cheesemaking is an age-old craft that has only grown in scale and quality with technological advancements. Creating a balance between microbial activity, moisture control, and aging conditions via microbiological, chemical, and physical manipulations is not an easy task, yet vacuum technology plays a huge part in simplifying this part of the cheesemaking process, improving hygiene, yield, and shelf life from beginning to end.

Once milk has been coagulated via rennet or acid, gel-like curd begins to form. This gel is cut using wire knives or mechanical blades repeatedly, and the gel begins to separate into solids and liquids. The solids are mainly made of casein and fats, while the liquid holds a suspension of everything else: proteins, sugars, and minerals.

This mixture is allowed to flow in one direction, and the solids (the curds) begin to compact, like a snowball rolling down a hill. At this stage, it would not be helpful to dewater the mixture, since the curds are still forming using the casein and fats in the liquid. However, the curds sink as they properly form, meaning that the very surface of the liquid can be removed. This is the whey, the leftover liquid suspension from curd formation, and vacuum is applied here to partially dewater the mixture, concentrating the liquid to maximize curd formation. Once the curds have formed sufficiently, the whole mix is heated and stirred to promote as much curd formation as possible, then dewatered. The whey can be dried and concentrated to make products like the whey protein so widely used in the world today. Without the application of vacuum, the ingredients of the curd take a staggering amount of time to reach the levels of formation that are seen now.

At this point, the curd has been dewatered, but each one is like a water balloon since it was formed underwater: water molecules are inevitably tied within the matrix of proteins and fats. Here, the curds are gathered together and pressed to squeeze out the water. Depending on the type of cheese, they can be stacked, cut, and pressed repeatedly until the desired consistency is achieved.

Starting from the pressing process, each cheese will undergo different treatments. Some, like Parmesan, may involve culture-specific processes and long periods of aging in a regulated environment while others, like mozzarella, can be made by stretching the curds after they are pressed and forming them into a ball.

After the cheese is completed, it must be stored and distributed in a way that discourages further microbial activity and slows the degrading of the cheese over time. Modified Atmospheric Packaging (MAP) has an enormous impact for this predicament: by vacuum-sealing the plastic packaging for the cheese, external oxidating agents and microorganisms are pulled out and kept out from within the packaging. In this manner, cheese boasts a much longer shelf life, allowing for comfortable storage and distribution while maintaining a reputation for quality and flavor.

For the cheese to be properly secured in these packages, however, the packages first must be designed and produced. In some cases, one may find that the packages have been specifically engineered and made for a client in cheese. This is where thermoforming comes in: a client in cheesemaking makes a request for certain parameters to a package production facility. A mold is designed and crafted carefully, then positioned in the production line. This line includes a heating element and a continuous sheet of plastic. A section of the sheet is heated, then carefully lowered onto the mold. This mold has small holes within it that are connected directly to the line’s vacuum system, pulling the heated sheet tight onto the mold as it cools. The newly formed tray or package is cut from the rest of the sheet, and the cycle continues. Thanks to the implementation of a vacuum system, the package can be much more complex than a simple box or can, allowing for even more efficient packaging ratios and tighter vacuum sealing.

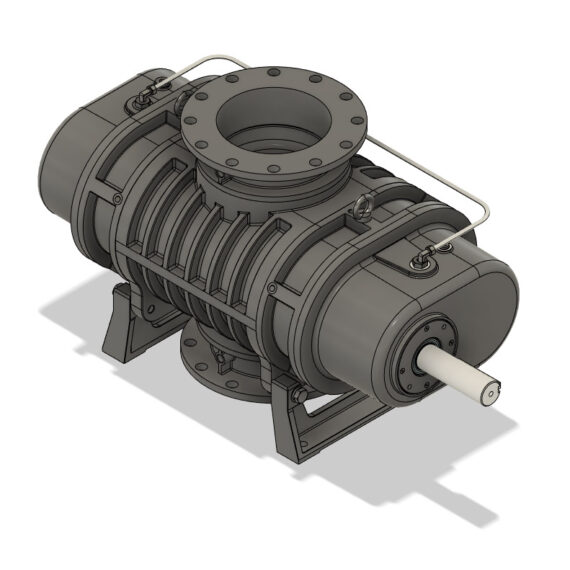

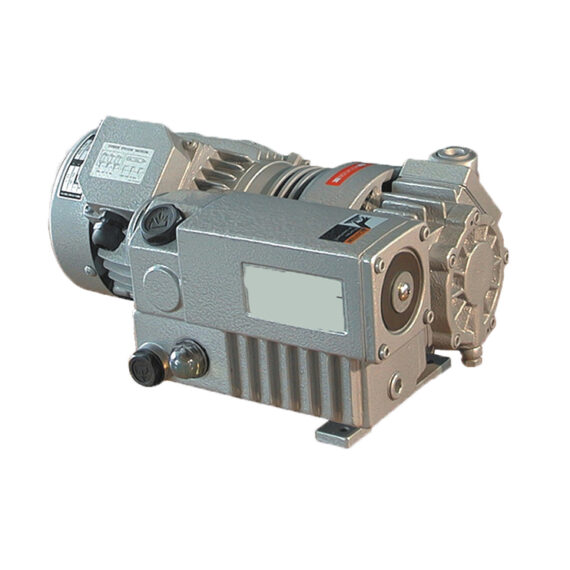

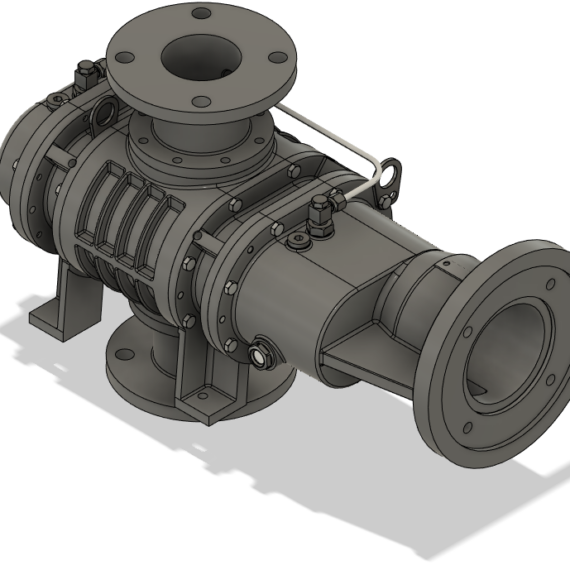

Vacuum provides critical support in moisture removal, product formation, package engineering, and preservation that shapes the very core of industrial cheesemaking. NES Company Inc. supports dairy processors with vacuum pumps and custom-engineered process vacuum systems for each and every application found in the cheesemaking industry.