Rotary Vane Pumps for the Automotive Industry

Technological advancements in the automotive industry have made it easier, safer, and cheaper to drive. Stopping, turning, and going faster are made more efficient with the use of hydraulic pistons, accumulators, and valves.

The power steering system makes it easier to turn without having to turn the steering wheel all the way; the wheels are made more sensitive to the turning of the steering wheel. This can be done electronically or hydraulically. In the case of hydraulic power-assisted steering, a pump is powered by the engine and spins at a rate dependent on engine speed. It pulls hydraulic fluid and compresses it, exhausting it at high pressures. A rotary valve senses the rotation of the steering wheel, blocking the compressed transmission fluid from the fluid lines through the return lines back into the reservoir. When the steering wheel is turned, the fluid flows through the unblocked fluid lines to the hydraulic pistons that move the wheels.

Automatic transmission is still a relatively recent technological advancement. The standard manual transmission of the past required that the driver adjust the position of the transmission gears according to the engine speed by braking and clutching the transmission gears, adjusting them through the shifter. However, this can be a complicated process that requires much attention for the average driver. Instead, automatic transmission was created for convenience so that all a driver needs to do is shift the car into “driving gear”. Depending on the speed of the car, it will self-adjust using hydraulic pistons and accumulators. This equipment works together and clutches the gears on its own, changing the gearing according to the needs of the car at that moment. This innovation made the internal combustion engine-driven automobile simple and safe enough to be popularized across the world.

Power brakes are also hydraulic automotive systems. By depressing the brake pedal, a piston is depressed and sends hydraulic fluid from the master cylinder to the slave cylinders, actuating the hydraulic pistons near each wheel. The pistons actuate, clenching the brake pads against the disc and slowing the car.

Superchargers supply high concentrations of compressed air to internal combustion engines to increase the efficiency of the combustion rate, drawing more power out of the fuel. They make the car weigh much more, and its complex structure makes for difficult maintenance. However, the sheer increase in power output of the engine with the addition of a supercharger is indisputable. The supercharger supplies pressurized air to the radiator, which cools the air. The air needs to be cooled because of the heat of compression causing molecular friction. Once this is dealt with, the pressurized air is sent straight into the combustion chambers. The result is no lag and great horsepower while at low RPM. This means the car gets fast straight away without too much stress on the crankshaft.

Applications of Liquid Ring Vacuum Pumps

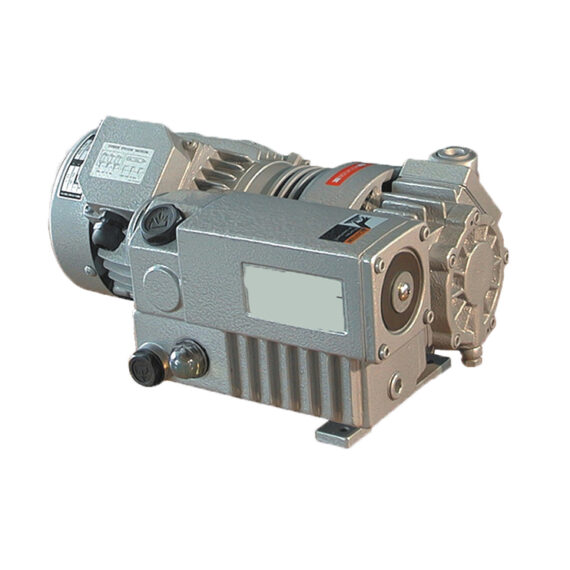

All of the aforementioned hydraulic automotive systems utilize a rotary vane vacuum pump. Vacuum apparati have innate compression capabilities on the medium it is transferring, unlike some other pumps which only shift matter from one end to another, such as a normal screw pump drawing water from one water source to another.

The power steering system utilizes the rotary vane vacuum pump to quickly supply hydraulic fluid to the wheels depending on the rotation of the steering wheel. Because there is a set amount of fluid that needs to be relocated constantly as the steering wheel turns, the exchange of fluid needs to be quick. The rotary vane pump acts as a rapid recirculator so that the rotary valve always has fluid to redirect. The hydraulic automatic transmission system is similar to the power steering system in that a set amount of hydraulic fluid needs to be transported at a rapid pace. A vacuum pump is utilized here so that the mass transfer can be done at a much higher rate. Power brakes are the third of the hydraulic automotive systems that need to move a set amount of hydraulic fluid at a rapid rate. Although much simpler of a mechanism, the inclusion of a vacuum pump allows for quicker response to the depression of the brake pedal as opposed to simply having only hydraulic lines and pistons in place.

A supercharger is a rotary vane vacuum pump, simply stated. The difference between the typical industrial rotary vane vacuum pump and a rotary vane supercharger is that the inlets span across the entire breadth of the apparatus, maximizing the concentration of oxygen allowed into the combustion chambers.

Advantages of Liquid Ring Vacuum Pumps

The rotary vane vacuum pump is perfect for the applications mentioned above. Although these rotary vane pumps are about the size of a human palm, they are incredibly efficient at the task set before them. Hydraulic fluid acts as a lubricant for the rotary vanes, creating minimal metal-to-metal contact via a thin hydraulic oil coating between the vanes and chamber and a stronger seal between vane and chamber for a higher achievable ultimate vacuum level.

The typical supercharger boasts about 115-200 PSI outlet conditions at anywhere from 150 to 300 CFM. It does not matter too much if there is rotary vane oil contamination in the outlet, as the power generation process is innately a dirty process anyway. The compressor provides an undisturbed flow of air to the engine and can handle smaller particulates in the air like dust. The vanes will need replacement after approximately every 20,000 miles. The rotary vane vacuum compressor of this size is relatively inexpensive depending on the application (personal vs. professional racing), lasts long, and does its job well.