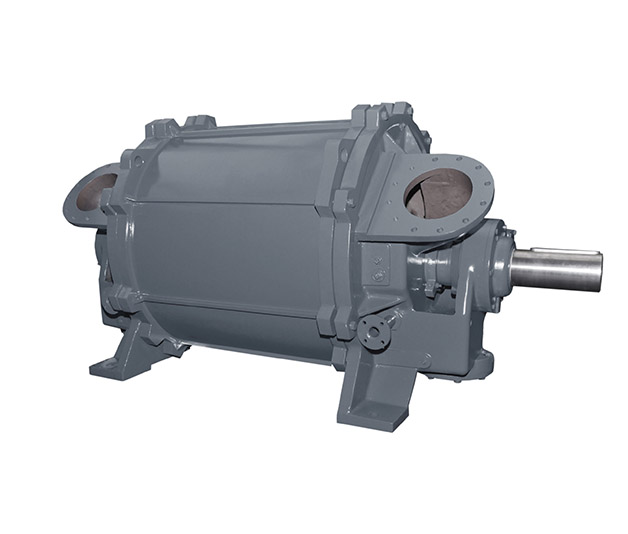

Interchangeable Nash Vacuum Pump & Compressor Spare Parts & Accessories

NES Company, Inc. competitively offers Nash replacement spare parts including cones, port plates, rotor shaft assemblies, heads, bodies, bearings, motors, couplings, gears, heat exchangers, control panels, sensors, valves and all other replacement parts for liquid ring vacuum pumps and compressors. Our portfolio encompasses direct part interchangeability for the Nash Classic 904 / 905, AT, CL, SC, TC, and Premier Series, as well as the Siemens L200 2BE Series.

About NES Spare Parts & Accessories

NES Company Inc has distributed spare parts and accessories for liquid ring vacuum pumps and compressors for decades. We offer drop-in replacements for Nash Classic series vacuum pumps and compressors with direct internal and external part interchangeability. NES is determined to hold the reputation of quality, responsiveness, and great pricing that we pride ourselves in. Speak with an expert today to learn about the spare part solutions NES Company can offer to get you out of the bind.

NES Company, Inc. provides quality through:

- Drawing Approval at PO

- API-Approved Foundry for Spare Parts

- Mirror Finish for Port Plates

- Rotor Shaft Assembly-balanced Standard ISO G2.5

- Shaft is ultrasound tested

- Pictures & Video of testing

- Chemical metallurgy report on each part

- Testing Standard PNEUROP, Nash Orifice Method

- Products conform to HEI Standard

Scroll / Drag to view >>>

| NES Model Drop-In | Nash Model |

|---|---|

| NL-401 | CL-401 |

| NL-402 | CL-402 |

| NL-403 | CL-403 |

| NL-701 | CL-701 |

| NL-702 | CL-702 |

| NL-703 | CL-703 |

| NL-1001 | CL-1001 |

| NL-1002 | CL-1002 |

| NL-1003 | CL-1003 |

| NL-1501 | CL-1501 |

| NL-1502 | CL-1502 |

| NL-2001 | CL-2001 |

| NL-2002 | CL-2002 |

| NL-2003 | CL-2003 |

| NL-3001 | CL-3001 |

| NL-3002 | CL-3002 |

| NL-3003 | CL-3003 |

| NL-4001 | CL-4001 |

| NL-4002 | CL-4002 |

| NL-4003 | CL-4003 |

| NL-6001 | CL-6001 |

| NL-6002 | CL-6002 |

| NL-6003 | CL-6003 |

| NL-9001 | CL-9001 |

| NL-9002 | CL-9002 |

| NL-9003 | CL-9003 |

| NL-9001G | CL-9001G |

| NL-9002G | CL-9002G |

| NL-9003G | CL-9003G |

| NL-14001 | CL-14001 |

| NL-14002 | CL-14002 |

| NL-14003 | CL-14003 |

| NL-14001G | CL-14001G |

| NL-14002G | CL-14002G |

| NL-14003G | CL-14003G |

Scroll / Drag to view >>>

| NES Model Drop-In | NASH Model |

|---|---|

| N904 L1 | 904 / 905 L1 |

| N904 L2 | 904 / 905 L2 |

| N904 M1 | 904 / 905 M1 |

| N904 M2 | 904 / 905 M2 |

| N904 P1 | 904 / 905 P1 |

| N904 P2 | 904 / 905 P2 |

| N904 P3 | 904 / 905 P3 |

| N904 R1 | 904 / 905 R1 |

| N904 R2 | 904 / 905 R2 |

| N904 R3 | 904 / 905 R3 |

| N904 S1 | 904 / 905 S1 |

| N904 S2 | 904 / 905 S2 |

| N904 S3 | 904 / 905 S3 |

| N904 T1 | 904 / 905 T1 |

| N904 T2 | 904 / 905 T2 |

| N904 T3 | 904 / 905 T3 |

| N904 U1 | 904 / 905 U1 |

| N904 U2 | 904 / 905 U2 |

Scroll / Drag to view >>>

| NES Model Drop-In | Nash Model |

|---|---|

| NTC-5 | TC-5 |

| NTC-7 | TC-7 |

| NTC-11 | TC-11 |

Scroll / Drag to view >>>

| NES Model Drop-In | NASH/Siemens Model |

|---|---|

| NBE 1-101 | L200 2BE 1-101 |

| NBE 1-102 | L200 2BE 1-102 |

| NBE 1-103 | L200 2BE 1-103 |

| NBE 1-151 | L200 2BE 1-151 |

| NBE 1-152 | L200 2BE 1-152 |

| NBE 1-153 | L200 2BE 1-153 |

| NBE 1-201 | L200 2BE 1-201 |

| NBE 1-202 | L200 2BE 1-202 |

| NBE 1-203 | L200 2BE 1-203 |

| NBE 1-251 | L200 2BE 1-251 |

| NBE 1-252 | L200 2BE 1-252 |

| NBE 1-253 | L200 2BE 1-253 |

| NBE 1-303 | L200 2BE 1-303 |

| NBE 1-305/306 | L200 2BE 1-305/306 |

| NBE 1-353 | L200 2BE 1-353 |

| NBE 1-355/356 | L200 2BE 1-355/356 |

| NBE 1-403 | L200 2BE 1-403 |

| NBE 1-405/406 | L200 2BE 1-405/406 |

| NBE 1-503 | L200 2BE 1-503 |

| NBE 1-505/506 | L200 2BE 1-505/506 |

| NBE 1-603 | L200 2BE 1-603 |

| NBE 1-605/606 | L200 2BE 1-605/606 |

| NBE 1-653 | L200 2BE 1-653 |

| NBE 1-655/656 | L200 2BE 1-655/656 |

| NBE 1-703 | L200 2BE 1-703 |

| NBE 1-705/706 | L200 2BE 1-705/706 |

| NBE 3/4-300/306 | L200 2BE 3/4-300/306 |

| NBE 3/4-320/326 | L200 2BE 3/4-320/326 |

| NBE 3/4-400/406 | L200 2BE 3/4-400/406 |

| NBE 3/4-420/426 | L200 2BE 3/4-420/426 |

| NBE 3/4-500/506 | L200 2BE 3/4-500/506 |

| NBE 3/4-520/526 | L200 2BE 3/4-520/526 |

| NBE 3/4-600/606 | L200 2BE 3/4-600/606 |

| NBE 3/4-620/626 | L200 2BE 3/4-620/626 |

| NBE 3/4-670/676 | L200 2BE 3/4-670/676 |

| NBE 3/4-720/726 | L200 2BE 3/4-720/726 |

Scroll / Drag to view >>>

| NES Model Drop-In | Nash Model |

|---|---|

| NAT-704 | AT-704 |

| NAT-706 | AT-706 |

| NAT-1004 | AT-1004 |

| NAT-1006 | AT-1006 |

| NAT-2004 | AT-2004 |

| NAT-2006 | AT-2006 |

| NAT-3004 | AT-3004 |

| NAT-3006 | AT-3006 |

Scroll / Drag to view >>>

| NES Model Drop-In | Nash Model |

|---|---|

| NC-2 | SC-2 |

| NC-3 | SC-3 |

| NC-4 | SC-4 |

| NC-5 | SC-5 |

| NC-6 | SC-6 |

| NC-7 | SC-7 |

| NC-9 | SC-9 |

| NC-10 | SC-10 |

| NC-11 | SC-11 |

Scroll / Drag to view >>>

| NES Model Drop-In | Nash Model |

|---|---|

| NP-2160 | Premier 2160 |

| NP-2200 | Premier 2200 |