Food Packaging Rotary Vane Vacuum Pumps & Compressors

Many methods of food preservation have been invented to keep food fresh for long amounts of time. However, many of these methods usually come at the cost of something else.

Salt preservation makes the food incredibly salty and dry when consumed. Freezing a food product causes the texture to deteriorate rapidly from the stresses caused by expansion as the ice crystallizes.

Sun-drying can vary in effect depending on the weather and humidity, smoking causes the food to partially cook and the smoky flavor is left behind, and using a controlled temperature/moisture chamber consumes much energy, attention, and finance in installation and operation. In terms of preservation for the sake of mass production and sale, none of these methods are optimal choices. Many methods have been combined, such as salting and smoking bacon, but nothing works quite as well to preserve the original condition of the food as using modified atmosphere packaging (MAP), commonly known as vacuum packaging. With the invention and continuous development of modified atmosphere packaging, mass production and sale of fresh or frozen organic produce was possible. As of now, there are three different general methods of MAP, distinct in procedure but similar in result.

Thermoforming packaging is a combination of two vacuum techniques that consists of creating the package right before stuffing it with food product. A plastic sheet is heated and pulled onto a custom positive cast using vacuum pressure. The vacuum pulls the air between the sheet and cast into itself to reduce the amount of bubbles, voids, or deformities in the shape of the packaging as much as possible. As soon as the packaging cools, it is conveyed to be filled, evacuated, and sealed.

Chamber sealing packaging involves locking a pre-packaged food in a chamber with the package open. The entire chamber is evacuated and the package is sealed within the chamber. This method employs Boyle’s law; if there is a low-pressure area in the chamber, any location with higher pressure will rush towards that area. If the area next to the pump piping is lower in pressure than any air that could be within the packaging, all the air in the packaging and food will rush out towards the pump.

Tray sealing packaging involves sealing and evacuating a plastic tray filled with food product. The tray is sealed with a microscopically perforated plastic film that is adhered or melted onto the tray. Either the tray is simply evacuated through the perforations, or it is evacuated while being filled with an inert gas, depending on the product. This gas can be helium, argon, carbon dioxide, or other depending on the sensitivity to chemical reaction of both the product and the package.

Applications of Liquid Ring Vacuum Pumps

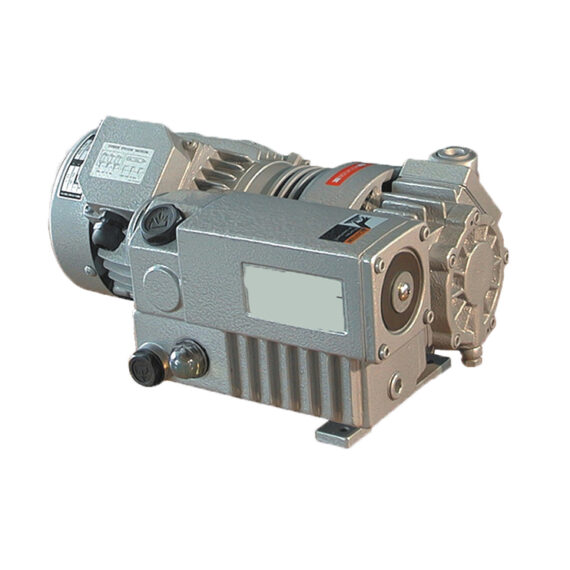

Modified atmosphere packaging protects the food product from oxidation, preventing food rotting or spoiling and vegetable browning and wilting. The vacuum also draws out any airborne microorganisms that can degrade the product as it is shipped and delivered. For these packaging applications, the oil-flooded rotary vane vacuum pump has long been the standard equipment.

In vacuum thermoforming packaging, two rotary vane vacuum pumps are used. One is used to form the food-safe plastic film into a thin container, and another is used to create vacuum conditions within the bag as it is being sealed after filling. Using the vacuum, the film is pulled onto a casting or mold and cooled until it takes its form without any air trapped between the film and the cast. In chamber sealing packaging, one rotary vane vacuum pump is used to evacuate the chamber as the packaging inside is being sealed after filling. Vacuum packaging involves using a vacuum pump to draw as much air as possible, along with any microorganisms and suspended particulate matter.

Advantages of Liquid Ring Vacuum Pumps

As a general standard, food packaging with the use of vacuum requires an approximate ultimate vacuum level of 100-300 mbar. With the additional step of vacuum forming in thermoforming packaging, the acceptable range becomes 100-250 mbar. Oil-sealed single-stage rotary vane vacuum pumps have been commonly used for food packaging applications of vacuum and suction.

One of the major drawbacks of oil-sealed rotary vane vacuum pumps is that it cannot process large contaminants or large amounts of contaminants. Large amounts of water will emulsify with the oil and create sludge, which will significantly hinder the performance of the rotary vane. Moderate amounts of dirt in the air would mix with the oil and cause clogging in any chamber, inlet filtration, outlet filtration, and oil recirculation system that it may encounter. Luckily, vacuum packaging processes clean air that is ventilated and monitored for food safety, so one of the largest disadvantages of the oil-circulated rotary vane is completely eliminated.

As for the advantages, our NRV Series oil-flooded rotary vane vacuum pumps achieve a wide range of both vacuum level and flow capacity. They are relatively inexpensive when compared to many other vacuum pumps. They are sturdy and simply designed for easy maintenance and sparse, quick repairs. The oil of the rotary vane allows for higher achievable ultimate vacuum pressure and longer lifespan for both the vane and the chamber. The oil acts as a barrier between moving metal-to-metal contact, and there is not much importance placed on the oil contamination concentration in the discharge gas because the discharge gas is simply ambient air and oil, not to be used anywhere else. The NES NRV Series new oil-circulated rotary vane lasts long with very easy maintenance and steady, constant suction at a wide range of mass transfer rates so that it can be tailored to the application.